Nov . 09, 2024 06:26 Back to list

EPDM Rubber Specification Sheet Overview and Key Properties Analysis

Introduction to EPDM Rubber Specifications and Applications

EPDM rubber, or Ethylene Propylene Diene Monomer rubber, is a type of synthetic rubber that has gained significant traction in various industries due to its impressive thermal, chemical, and weather resistance properties. This article will delve into the specifications of EPDM rubber, its unique characteristics, and a variety of applications where it excels.

Key Specifications of EPDM Rubber

EPDM rubber is commonly characterized by its distinct molecular structure, which consists of ethylene, propylene, and a diene component. This combination results in a highly versatile material with several noteworthy specifications

1. Temperature Resistance EPDM rubber boasts an impressive temperature range, typically enduring temperatures from -40°F to 250°F (-40°C to 121°C). This resilience makes it suitable for applications exposed to extreme heat or cold.

2. Chemical Resistance One of the standout features of EPDM rubber is its resistance to a variety of chemicals, including acids, alkalis, and oxygen. While it is not suitable for petroleum-based oils and hydrocarbons, its overall chemical stability is commendable.

3. Weathering Resistance EPDM is known for its excellent outdoor durability. Its resistance to UV, ozone, and weathering makes it an ideal choice for applications where prolonged exposure to the elements is a concern, such as roofing and automotive parts.

4. Flexibility and Resilience The material is renowned for its elasticity and flexibility, allowing it to maintain its shape and performance under stress. This characteristic is particularly valuable in applications that require materials to bend or compress without losing integrity.

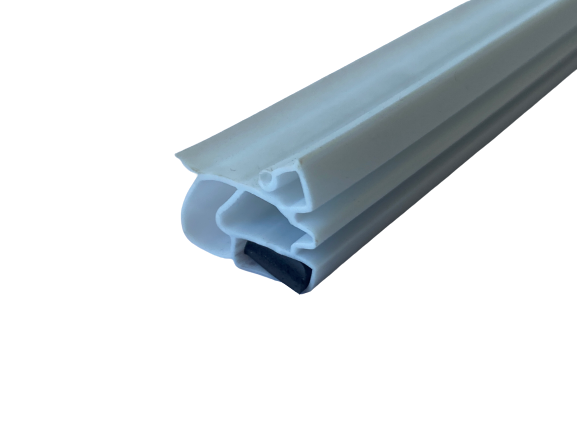

epdm rubber spec sheet

Applications of EPDM Rubber

The multifaceted properties of EPDM rubber lend themselves to a wide array of applications across various sectors

1. Automotive Industry In the automotive sector, EPDM rubber is widely used for seals, gaskets, and hoses due to its durability and ability to withstand high temperatures and exposure to weathering agents. This enhances the lifespan and efficiency of vehicle components.

2. Construction EPDM is a popular choice for roofing applications. Its membrane provides a waterproof barrier, effectively protecting buildings from leaks and moisture infiltration. Additionally, it is used in windows, doors, and various construction sealants.

3. Electrical and Electronics Due to its excellent electrical insulation properties, EPDM rubber is commonly found in electrical cable covers, connectors, and various electronic components. This ensures safety and reliability in electrical applications.

4. HVAC Systems In heating, ventilation, and air conditioning systems, EPDM rubber is used in seals, gaskets, and insulation, helping to enhance energy efficiency and maintain consistent temperatures.

5. Consumer Products EPDM rubber is also present in numerous consumer products, including toys, mats, and various household items. Its safety, durability, and resistance to aging make it an excellent material choice for everyday use.

Conclusion

EPDM rubber is a material of choice for many industries, thanks to its exceptional properties and versatility. Its resistance to temperature extremes, chemicals, and weathering makes it ideal for both demanding industrial applications and everyday consumer products. As technology and manufacturing methods continue to evolve, the applications for EPDM rubber will likely expand, further solidifying its role as an essential material in modern manufacturing and construction. Whether in the automotive industry or the realm of construction, EPDM rubber continues to prove its worth as a reliable and resourceful material for various applications.