Nov . 17, 2024 23:55 Back to list

famous customizable marine fender rubber sealing strip

Customizable Marine Fender Rubber Sealing Strips Enhancing Maritime Safety and Efficiency

In the maritime industry, ensuring the safety of vessels is of paramount importance. One of the critical components that contribute to this safety is the marine fender system. Marine fenders provide cushioning during collisions between vessels and docking structures, helping to prevent damage to both. Among these fender systems, customizable marine fender rubber sealing strips have emerged as a crucial innovation, offering tailored solutions for varied maritime applications.

The Importance of Rubber Sealing Strips

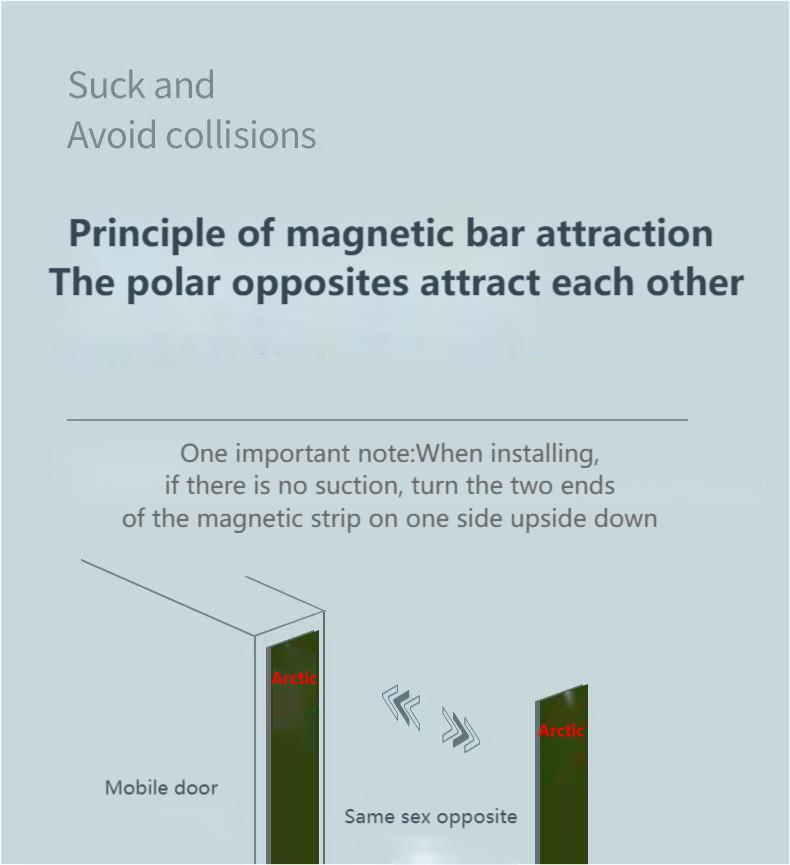

Rubber sealing strips play a vital role in the performance of marine fenders. They are designed to create a durable interface between the fender and the contacting surface—whether that be a ship hull, dock, or another vessel. These sealing strips not only absorb impacts but also prevent water ingress, which is essential for maintaining buoyancy and stability. The use of high-quality rubber materials ensures that these strips can withstand harsh marine environments, including salty water, UV exposure, and extreme temperatures.

Customization A Key Advantage

One of the standout features of modern marine fender rubber sealing strips is their customizable nature. Different vessels have unique designs, sizes, and operational requirements, and a one-size-fits-all approach can result in inadequate protection or even damage. Customizable rubber sealing strips allow for specific adaptations to fit the unique geometry and operational context of each vessel.

Customization options may include dimensions, material hardness, and color. For example, a vessel operating in a high-impact area may require thicker, harder rubber strips, while another vessel frequently navigating delicate ecosystems might benefit from softer materials that offer gentler contact with surroundings. Moreover, various colors can help in the identification of specific fender systems, which can be crucial in busy ports or during rescue operations.

famous customizable marine fender rubber sealing strip

Material Selection and Engineering

The performance of marine fender rubber sealing strips is heavily dependent on the selection of materials. High-performance rubber compounds are engineered to provide optimal elasticity, durability, and resistance to wear. Manufacturers often conduct extensive testing to ensure that the rubber not only meets marine industry standards but can also endure the specific environmental conditions it will face.

Additionally, advancements in material technology have led to the development of eco-friendly rubber options. Such materials are designed to minimize environmental impact while maintaining high performance, aligning with the growing industry emphasis on sustainability.

Installation and Maintenance

Proper installation of customizable marine fender rubber sealing strips is essential for maximizing their effectiveness. Skilled professionals usually ensure that the strips are accurately fitted and securely attached to the fender systems. Regular maintenance checks are also crucial; these should include inspections for wear and tear, as well as evaluations of the sealing strips' effectiveness in protecting against impacts and water ingress.

Conclusion

Customizable marine fender rubber sealing strips represent a significant advancement in maritime technology. By offering tailored solutions, they enhance safety, operational efficiency, and environmental protection in various maritime contexts. As the industry continues to evolve, the importance of adaptive technologies like customizable rubber sealing strips cannot be overstated. Their integration into marine fender systems plays a critical role in safeguarding both vessels and marine environments, contributing to a more secure and sustainable maritime future. With ongoing innovations, these rubber sealing strips will likely continue to improve, addressing the ever-changing demands of the maritime industry.

Next:

Prev: