Nov . 04, 2024 21:42 Back to list

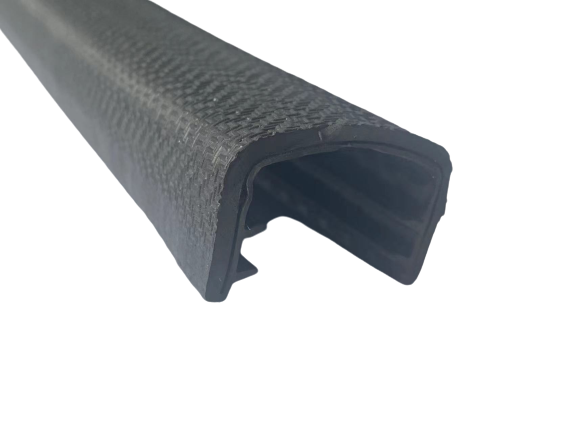

famous epdm automotive fuel tank gasket

The Importance of EPDM Automotive Fuel Tank Gaskets

In the automotive industry, ensuring the integrity and reliability of fuel systems is of paramount importance. One component that plays a crucial role in this aspect is the fuel tank gasket. When it comes to fuel tank gaskets, Ethylene Propylene Diene Monomer (EPDM) is a standout material that offers numerous advantages. Understanding the significance of EPDM automotive fuel tank gaskets can contribute to improved vehicle performance and longevity.

What is EPDM?

EPDM is a type of synthetic rubber known for its excellent resistance to heat, ozone, and weathering. It is widely used in various automotive applications due to its superior properties compared to traditional rubber. EPDM can withstand a wide range of temperatures, making it ideal for fuel tank applications that encounter fluctuating conditions. Its durability significantly reduces the likelihood of leakage, which is crucial for maintaining fuel efficiency and ensuring vehicle safety.

Key Advantages of EPDM Fuel Tank Gaskets

1. Chemical Resistance One of the primary benefits of EPDM is its outstanding chemical resistance. Automotive fuel systems are subject to various fuels, including gasoline, diesel, and alternative fuels. EPDM gaskets can handle these substances without degrading or losing their sealing properties, which helps in preventing fuel leaks.

2. Temperature Tolerance EPDM maintains its elasticity and performance across a wide temperature range, typically from -40°F to 250°F (-40°C to 121°C). This characteristic is vital for automotive applications, especially where temperatures can fluctuate dramatically due to engine heat or environmental conditions.

3. Compression Set Resistance Over time, materials used in gaskets can lose their ability to compress and seal effectively, a phenomenon known as compression set. EPDM gaskets exhibit excellent resistance to this, which helps them maintain a reliable seal throughout their lifecycle.

famous epdm automotive fuel tank gasket

4. Environmental Resistance EPDM is designed to withstand harsh environmental conditions, including UV radiation, ozone exposure, and general weathering. This durability is essential for fuel tank gaskets, which are often subjected to outdoor elements, ensuring they maintain functionality over extended periods.

5. Cost-Effectiveness While high-quality materials sometimes come with a higher initial cost, the longevity and reliability of EPDM gaskets make them a cost-effective choice in the long run. They can reduce maintenance needs and costly repairs related to fuel leaks.

Applications in Automotive Use

EPDM fuel tank gaskets are crucial in several automotive contexts. They are utilized in both OEM (Original Equipment Manufacturer) components and aftermarket replacements. Their application extends to various vehicle types, including cars, trucks, buses, and even performance vehicles where the fuel system's efficiency is critical.

With the rise of electric vehicles (EVs), the automotive landscape is rapidly changing. However, even in hybrid or fully electric systems, there are still applications where traditional fuel systems are present. EPDM gaskets will continue to play a vital role in ensuring these systems function safely and efficiently, particularly as the market transitions to alternative fuel vehicles.

Conclusion

In conclusion, EPDM automotive fuel tank gaskets are an essential component in modern vehicles, providing reliability, durability, and performance. Their ability to resist chemical degradation, tolerate a wide range of temperatures, and maintain a reliable seal over time makes them an ideal choice for automotive manufacturers and service providers. As the automotive industry continues to evolve, the importance of high-quality components like EPDM gaskets cannot be overstated. For vehicle owners and manufacturers alike, investing in EPDM fuel tank gaskets translates to enhanced safety, efficiency, and overall vehicle performance. As automotive technologies advance, the demand for innovative materials will only intensify, reinforcing the role of EPDM as a dependable choice in fuel management systems.