Oct . 15, 2024 00:03 Back to list

famous marine fender rubber sealing strip

The Importance of Marine Fender Rubber Sealing Strips

Marine operations are vital for global trade, and one of the critical components ensuring the safety and efficiency of such operations is the marine fender system. At the heart of these systems often lies an essential yet often overlooked component the marine fender rubber sealing strip. This article explores its significance, functionality, and benefits within the maritime industry.

What are Marine Fender Rubber Sealing Strips?

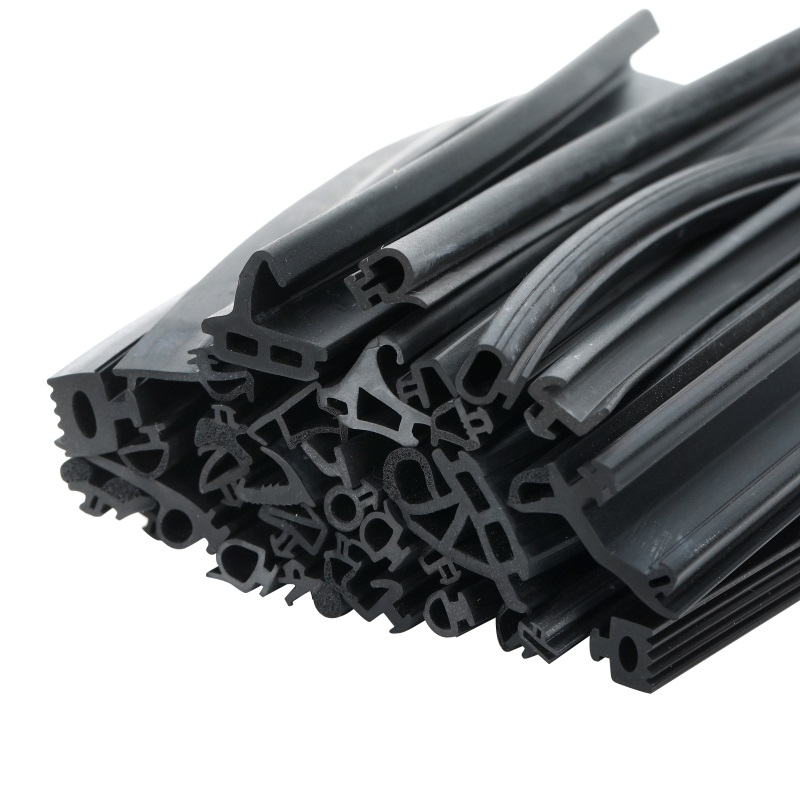

Marine fender rubber sealing strips are specifically designed components that work in conjunction with marine fenders. These strips are typically made from high-quality rubber materials that exhibit excellent durability, flexibility, and resistance to harsh marine environments. The primary purpose of these sealing strips is to enhance the performance of fenders, which are vital for absorbing the energy generated during the berthing and docking of vessels.

Functionality and Benefits

1. Energy Absorption One of the primary functions of marine fender rubber sealing strips is to improve the energy absorption characteristics of the fender system. When a vessel makes contact with the fender, the sealing strip helps in absorbing and dissipating the kinetic energy, thereby protecting both the vessel and the structure of the dock. This energy attenuation minimizes the risk of damage, thereby reducing maintenance costs and downtime.

famous marine fender rubber sealing strip

2. Water Resistance Marine environments are prone to challenges such as moisture and corrosion. Rubber sealing strips are engineered to provide excellent water resistance, which helps to prolong the life of the fender and the overall structure. By creating a watertight seal, these strips prevent water ingress that can lead to deterioration or damage over time.

3. Cost-Effectiveness Investing in high-quality marine fender rubber sealing strips can significantly reduce long-term operational costs. By preventing wear and tear on the fender itself and the docking infrastructure, these strips contribute to less frequent repairs and replacements. Thus, companies can save on construction and maintenance expenses associated with marine facilities.

4. Versatility and Customization Marine environments vary widely, and so do the types of vessels that dock at these facilities. Rubber sealing strips can be customized in terms of size, shape, and material properties to suit specific requirements. Whether for large cargo ships, ferries, or small recreational boats, these strips can be tailored to ensure optimal performance and protection.

5. Environmental Compliance With increasing regulations surrounding environmental protection, marine operations are under scrutiny to ensure they minimize their ecological footprint. Utilizing rubber sealing strips that are made from eco-friendly materials helps companies comply with regulations while maintaining operational efficiency.

Conclusion

In conclusion, marine fender rubber sealing strips may not be the most visible components of marine operations, but their role is undeniably crucial. From enhancing energy absorption capabilities to providing water resistance and cost-effectiveness, these strips contribute significantly to the safety and longevity of both vessels and docking structures. Additionally, their versatility and potential for customization make them ideal for various marine applications. As the maritime industry continues to evolve, investing in high-quality marine fender rubber sealing strips will remain a best practice for ensuring efficient and safe marine operations.

Next:

Prev: