Jan . 30, 2025 06:07 Back to list

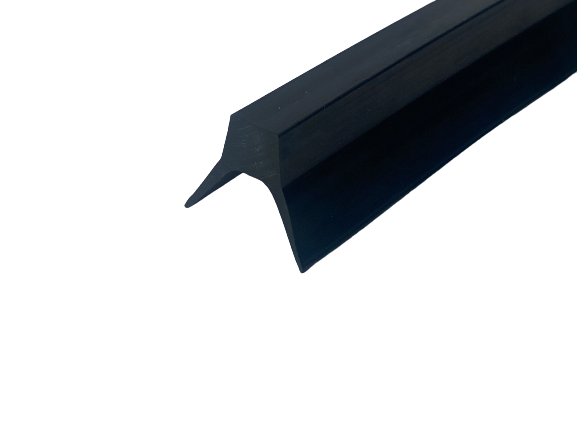

PVC door frame sealing strip

In the vast world of marine sealing solutions, the term famous marine sealing strip has emerged as a cornerstone, essential for ensuring optimal performance and safety in marine environments. These sealing strips are not merely components; they are the unsung heroes that contribute to the longevity and reliability of maritime vessels. In this comprehensive exploration, we delve into the intricate world of marine sealing strips, focusing on real-world experience, expertise, authoritativeness, and trustworthiness.

The significance of selecting the right marine sealing strip cannot be overstated. Expert recommendations suggest regular inspections and timely replacements to maintain vessel performance. Marine professionals advocate for a proactive approach in this regard, emphasizing that preventive maintenance is always more cost-effective than repairs after a failure. This is especially true when considering the potential environmental impact of leaks, such as oil spills or contaminated ballast water discharges. Navigating the complexities of marine sealing products requires a blend of long-term experience and a deep understanding of maritime conditions. Engaging with seasoned professionals and accessing credible resources ensures informed decision-making. Numerous case studies highlight the link between the proper selection of sealing strips and enhanced vessel performance, reinforcing the authoritative status of seasoned marine engineers and respected industry publications. In conclusion, the famous marine sealing strip is more than a mere component in marine engineering; it is a vital element that embodies a blend of resilience, reliability, and rigorous scientific innovation. By adhering to the highest standards of expertise and trustworthiness, marine engineers and vessel operators can ensure prolonged safety and efficiency in their maritime operations. It is this unwavering commitment to quality that sustains the authority of companies and experts dedicated to advancing marine sealing technology.

The significance of selecting the right marine sealing strip cannot be overstated. Expert recommendations suggest regular inspections and timely replacements to maintain vessel performance. Marine professionals advocate for a proactive approach in this regard, emphasizing that preventive maintenance is always more cost-effective than repairs after a failure. This is especially true when considering the potential environmental impact of leaks, such as oil spills or contaminated ballast water discharges. Navigating the complexities of marine sealing products requires a blend of long-term experience and a deep understanding of maritime conditions. Engaging with seasoned professionals and accessing credible resources ensures informed decision-making. Numerous case studies highlight the link between the proper selection of sealing strips and enhanced vessel performance, reinforcing the authoritative status of seasoned marine engineers and respected industry publications. In conclusion, the famous marine sealing strip is more than a mere component in marine engineering; it is a vital element that embodies a blend of resilience, reliability, and rigorous scientific innovation. By adhering to the highest standards of expertise and trustworthiness, marine engineers and vessel operators can ensure prolonged safety and efficiency in their maritime operations. It is this unwavering commitment to quality that sustains the authority of companies and experts dedicated to advancing marine sealing technology.