Nov . 17, 2024 09:38 Back to list

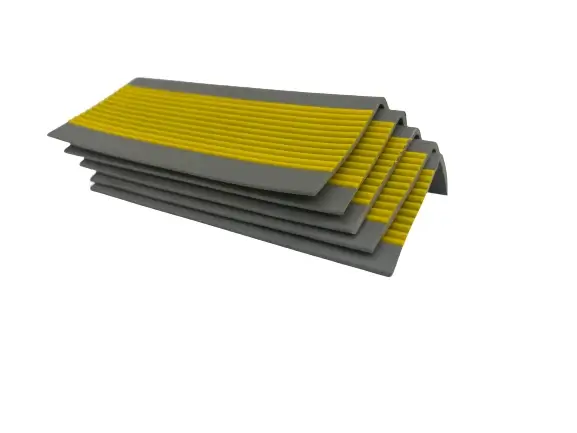

High-Quality Rubber Sheets in Various Thicknesses for Versatile Applications

The Versatility of Famous NBR Rubber Sheets A Comprehensive Overview

Nitrile Butadiene Rubber (NBR), commonly known as nitrile rubber, has gained immense popularity in a variety of industries due to its excellent properties and versatility. One of the most sought-after forms of this material is the NBR rubber sheet, particularly in thicknesses ranging from 1 to 20 mm. This article explores the features, applications, and benefits of famous NBR rubber sheets, highlighting why they are a preferred choice for many businesses.

Properties of NBR Rubber Sheets

NBR rubber sheets are renowned for their remarkable resistance to oils, fuels, and chemicals, making them an ideal material for applications in the automotive, aerospace, and manufacturing sectors. The material exhibits a strong resistance to abrasion, which aids in prolonging its longevity even in challenging environments. Additionally, NBR rubber sheets can tolerate a wide range of temperatures, typically ranging from -40°C to 120°C, while maintaining their structural integrity.

The sheets are available in various thicknesses, with 1 to 20 mm being the most common for industrial applications. This variability allows manufacturers and engineers to select the right thickness for specific needs, whether for gasketing, sealing, or cushioning applications.

Applications of NBR Rubber Sheets

The versatility of NBR rubber sheets has contributed to their widespread adoption across numerous industries. In the automotive industry, they are often used for seals, gaskets, and hoses, where resistance to petroleum-based products is essential. In the construction field, NBR rubber sheets are employed in protective coverings and as insulation materials due to their durability and weather resistance.

famous nbr rubber 1~20mm rubber sheet

Furthermore, in the food processing industry, specific grades of NBR rubber are designed to comply with an array of health and safety regulations. These sheets ensure that the safety and integrity of food products are maintained while providing the necessary resilience against common cleaning agents and temperature fluctuations.

Benefits of Using NBR Rubber Sheets

One of the most significant benefits of NBR rubber sheets is their cost-effectiveness. Compared to other types of rubber, NBR offers a balanced combination of performance and affordability, making it accessible for companies of all sizes. Additionally, the easy availability of these sheets in various grades and thicknesses means that manufacturers can find a suitable option tailored to their exact specifications.

Moreover, NBR rubber’s resilience contributes to reduced maintenance and replacement costs, as components made from this material tend to have a longer service life. This reliability not only enhances operational efficiency but also serves to minimize downtime in production environments.

Conclusion

In conclusion, famous NBR rubber sheets are a cornerstone material in various industries due to their unique properties and adaptability. With thickness options ranging from 1 to 20 mm, businesses can leverage the many benefits of NBR rubber to improve their operational efficiencies. Its effectiveness in challenging environments, coupled with its cost advantages, ensures that NBR rubber sheets will continue to be in high demand for years to come. Whether in automotive, construction, or food processing sectors, these rubber sheets provide robust solutions that meet the needs of modern industry demands.