Dec . 16, 2024 14:40 Back to list

Innovative Design of Renowned Ship Sealing Strips for Enhanced Marine Performance

The Importance of Famous Ship Sealing Strips in Maritime Engineering

In the realm of maritime engineering, the sealing strip plays an integral role in ensuring the safety, efficiency, and longevity of ships. These unassuming yet crucial components are often overlooked by the casual observer, yet their importance cannot be overstated. The topic of “famous ship sealing strips” brings to light the innovations and engineering prowess that have evolved over the centuries to protect vessels from the harsh marine environment.

The Importance of Famous Ship Sealing Strips in Maritime Engineering

One of the most celebrated examples of ship sealing technology is the use of strip seals in submarine design. Submarines, which operate under immense pressure and in complete darkness, rely on sealing strips to keep water out and ensure crew safety. The design of these seals is precisely engineered to withstand fluctuating pressures and provide a reliable barrier against the surrounding water. Innovations such as hydraulic sealing systems and advanced polymer materials have given rise to some of the most effective sealing solutions in modern maritime engineering.

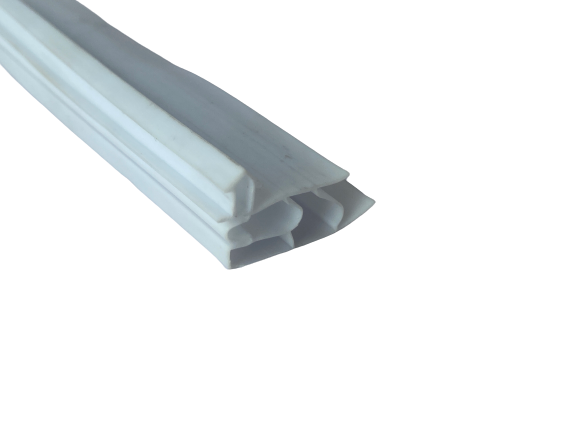

famous ship sealing strip

Famous vessels, such as the RMS Titanic, also highlight the significance of effective sealing strips. While Titanic is often remembered for its tragic sinking, the lessons learned from that disaster have led to significant advancements in sealing technology. Engineers recognized that many of the compartments in the ship did not have effective seals, allowing water to flood various sections rapidly. Today, modern ships are designed with watertight compartments and advanced sealing solutions to enhance safety and prevent similar disasters.

Moreover, the maritime industry continually invests in research and development to innovate sealing technology further. The introduction of advanced materials, such as thermoplastic elastomers and silicone, has expanded the life and reliability of sealing strips. These materials are designed to withstand extreme temperature variations and resist corrosion, ensuring that ships remain seaworthy over extended periods. Additionally, enhanced manufacturing processes, including precision molding and extrusion techniques, have improved the consistency and quality of sealing strips, contributing to the overall safety of maritime transport.

Sustainable practices are also becoming a priority in sealing strip manufacturing. With the growing emphasis on eco-friendly materials and processes, many companies are now producing biodegradable and recyclable sealing solutions. This shift not only addresses environmental concerns but also helps to reduce the carbon footprint associated with shipbuilding and maintenance.

In summary, the world of maritime engineering relies heavily on the effectiveness of sealing strips in ensuring the performance and safety of ships. As illustrated by famous vessels and ongoing innovation in sealing technology, the importance of these components cannot be ignored. Modern engineering has given rise to more reliable, durable, and sustainable sealing solutions, ultimately leading to safer voyages on the high seas. The continuous investment in research and development promises further advancements in sealing technology, making the maritime industry increasingly resilient against the challenges posed by the ocean. As we look toward the future, it is clear that sealing strips will remain a topic of significant importance in maritime engineering, symbolizing the vital relationship between human ingenuity and the relentless forces of nature.