Aug . 21, 2024 04:03 Back to list

Flexible White Neoprene Rubber Strips for Versatile Applications and Custom Solutions

The Versatility of White Neoprene Rubber Strips

Neoprene, a family of synthetic rubbers, has garnered significant attention in various industries for its remarkable properties. Among the different forms of neoprene products, white neoprene rubber strips stand out due to their unique characteristics and versatility. This article explores the features, applications, and advantages of using white neoprene rubber strips in diverse sectors.

What is Neoprene?

Neoprene, also known as polychloroprene, is a type of synthetic rubber that was first developed in the 1930s. It is created through the polymerization of chloroprene, which results in a material that is both flexible and resilient. Neoprene is highly resistant to water, chemicals, and thermal fluctuations, making it an ideal choice for various applications. The white variant of neoprene rubber strips is particularly popular due to its aesthetic appeal and specific functional properties.

Features of White Neoprene Rubber Strips

1. Aesthetic Appeal The white color of neoprene rubber strips gives a clean and professional appearance, making them suitable for applications where visual aesthetics are important, such as in retail displays or customized products.

2. Durability and Strength White neoprene rubber strips are known for their strength and durability, capable of withstanding wear and tear in high-demand environments. Their elasticity enables them to maintain their shape and function even when subjected to stress.

3. Chemical Resistance These strips offer excellent resistance to a wide range of chemicals, including oils, greases, and solvents. This characteristic makes them valuable in industries like automotive, manufacturing, and laboratory settings.

4. Weather Resistance Neoprene is inherently resistant to degradation from exposure to UV light, ozone, and harsh weather conditions. As a result, white neoprene rubber strips are suitable for outdoor applications, ensuring longevity even in challenging environments.

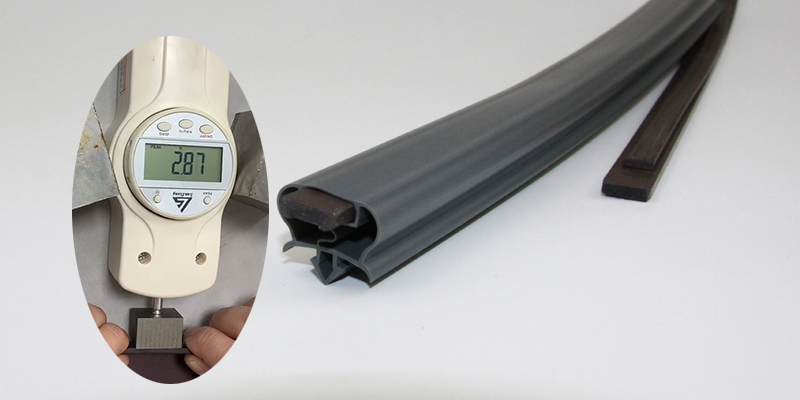

white neoprene rubber strips

5. Temperature Tolerance The ability to retain functionality across a broad temperature range is another essential feature of neoprene. This adaptability allows white neoprene rubber strips to be used in applications involving both cold and hot conditions.

Applications of White Neoprene Rubber Strips

1. Sealants and Gaskets One of the primary uses of white neoprene rubber strips is in creating seals and gaskets. Their elasticity and compressibility allow them to form tight seals that prevent the leakage of gases or liquids in various machinery and equipment.

2. Electrical Insulation In the electronics industry, white neoprene rubber strips are utilized for their electrical insulating properties. They provide protection against moisture and electrical currents, contributing to the safety and reliability of electrical devices.

3. Protective Padding These strips can serve as protective padding in various applications, including sports gear and protective equipment. Their cushioning properties help absorb shock and reduce the risk of injury.

4. Consumer Goods Manufacturers often use white neoprene rubber strips in consumer products such as laptop sleeves, bags, and accessories, where both protection and aesthetics matter.

5. Automotive Applications In the automotive industry, these strips are useful for acoustical insulation and vibration dampening, improving the overall performance and comfort of vehicles.

Conclusion

White neoprene rubber strips exemplify the blend of functionality and versatility that makes neoprene a preferred material in numerous industries. With their aesthetic appeal, durability, and resistance to a variety of environmental factors, these strips can support a wide range of applications, from industrial uses to consumer goods. As industries continue to innovate, the demand for high-quality neoprene products, including white neoprene rubber strips, is likely to grow, reinforcing their importance in modern manufacturing and design.