Aug . 06, 2024 08:17 Back to list

High-Performance EPDM Gaskets for Automotive Fuel Tanks Ensuring Leak Resistance and Durability

EPDM Automotive Fuel Tank Gasket A Vital Component for Vehicle Performance

In the automotive industry, the integrity of fuel systems is paramount for ensuring vehicle performance, efficiency, and safety. One of the unsung heroes of this system is the gasket, specifically made from Ethylene Propylene Diene Monomer (EPDM) rubber. This material is not only versatile but is also uniquely suited for use in fuel tank gaskets due to its exceptional properties.

What is EPDM?

EPDM is a synthetic rubber that is characterized by its excellent weather resistance, thermal stability, and durability. It consists of ethylene, propylene, and a diene monomer, which contribute to its impressive resilience against a variety of environmental factors. These factors include exposure to ozone, ultraviolet light, and extreme temperatures—conditions that automotive components often encounter.

Importance of Fuel Tank Gaskets

A fuel tank gasket serves as a critical seal that prevents fuel leaks and protects the fuel system from contaminants. This is essential not only for the vehicle’s performance but also for safety reasons. Fuel leaks can lead to hazardous situations, including fires and environmental damage. Thus, selecting the appropriate material for the gasket is crucial.

Advantages of EPDM for Fuel Tank Gaskets

1. Chemical Resistance EPDM exhibits excellent resistance to fuels and oils, making it a perfect material for gaskets that are in constant contact with gasoline and diesel. This resistance ensures that the gasket maintains its integrity over time, reducing the risk of leaks.

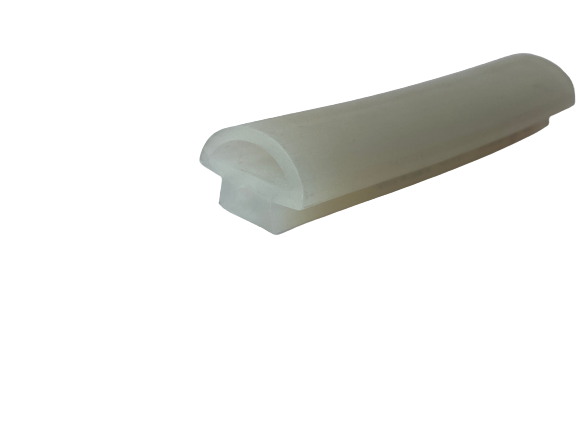

epdm automotive fuel tank gasket product

2. Temperature Stability Vehicles experience a wide range of temperatures, from freezing conditions to extreme heat during engine operation. EPDM can effectively handle these temperature fluctuations without degrading, elongating its lifespan and ensuring reliable performance.

3. Ozone and UV Resistance Automotive components are often exposed to sunlight and atmospheric conditions, which can lead to deterioration over time. EPDM's resistance to ozone and UV radiation ensures that the gasket remains pliable and effective, regardless of environmental conditions.

4. Ease of Manufacturing The flexibility of EPDM allows for precise molding into complex shapes, which is essential for achieving a perfect fit in the fuel tank assembly. This manufacturing capability ensures that each gasket can be produced to exact specifications, minimizing the potential for installation errors that could lead to leaks.

The Role of EPDM Gaskets in Sustainability

As the automotive industry shifts towards sustainability and eco-friendliness, EPDM gaskets present additional advantages. The material can be recycled, and its durability contributes to reduced waste by decreasing the frequency of replacements. Given the increasing emphasis on reducing carbon footprints, using materials like EPDM in automotive applications aligns with these environmental goals.

Conclusion

In conclusion, EPDM automotive fuel tank gaskets are essential components that play a significant role in the safety, performance, and efficiency of vehicles. With their exceptional resistance to chemicals, temperature fluctuations, and environmental stresses, they provide a reliable seal that helps prevent fuel leaks and maintains fuel system integrity. Given the ongoing advancements in automotive technology and the growing importance placed on sustainability, EPDM gaskets are likely to remain a key element in the evolution of automotive fuel systems. Investing in high-quality EPDM gaskets not only enhances the longevity and performance of the vehicle but also aligns with modern environmental standards.