Aug . 12, 2024 14:44 Back to list

High-Performance Marine Sealing Strip Solutions for Enhanced Durability and Effective Weather Resistance

Marine Sealing Strips Importance and Applications

Marine sealing strips are essential components in the marine industry, designed to protect vessels from the harsh environments of water and weather. These strips serve multiple purposes, including sealing joints, preventing water ingress, and ensuring the structural integrity of boats and ships. As the demand for durable and reliable marine equipment grows, so does the importance of high-quality sealing solutions.

What Are Marine Sealing Strips?

Marine sealing strips, often made from advanced materials such as EPDM rubber, silicone, or polyurethane, are specialized barriers designed to block water, dirt, and contaminants from entering critical areas of a vessel. Their application can be found in various parts of boats and ships, including doors, hatches, windows, and other access points. Because marine environments can be incredibly demanding, the sealing strips are typically engineered to withstand extreme temperatures, UV radiation, and saltwater exposure.

Key Benefits of Marine Sealing Strips

1. Waterproof Protection The primary function of marine sealing strips is to create a watertight seal. This is crucial for preventing leaks that can lead to significant damage or even sinking. By effectively blocking water ingress, these sealing strips enhance the safety and longevity of marine vessels.

2. Durability Given their exposure to the elements, marine sealing strips are designed for durability. High-quality materials resist wear and tear, ensuring that the strips maintain their sealing properties over time. This durability reduces the need for frequent replacements, saving time and maintenance costs for vessel owners.

3. Noise Reduction Besides their sealing capabilities, these strips also help in reducing noise and vibration within the cabin of the vessel. This creates a more comfortable experience for passengers and crew alike, contributing to overall satisfaction with the marine craft.

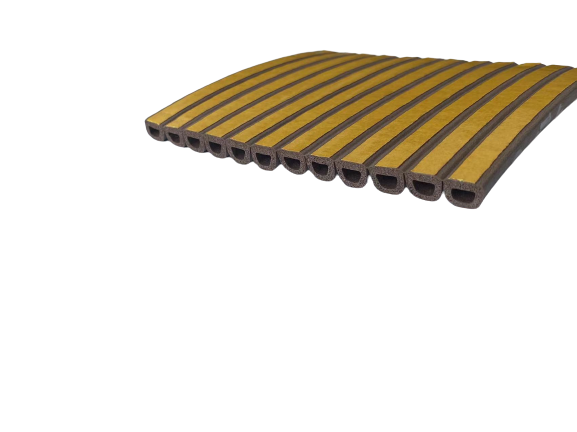

marine sealing strip product

4. Energy Efficiency Effective sealing can significantly improve a vessel's energy efficiency. By preventing drafts and leaks, marine sealing strips help to maintain internal temperatures, reducing the energy required for heating or cooling systems.

5. Customization Marine sealing strips come in various shapes, sizes, and materials. Manufacturers often provide custom solutions to meet specific needs, ensuring that the sealing strips fit perfectly in their intended locations. This customization further enhances their effectiveness.

Applications of Marine Sealing Strips

Marine sealing strips are versatile and can be used in various applications within the marine industry. Some common uses include

- Boat Doors and Hatches Where water or elements can easily enter, sealing strips help maintain a dry environment. - Windows and Portlights Sealing strips contribute to the integrity of windows, preventing leaks and enhancing visibility. - Engine Compartment A vital area that requires sealing to prevent water damage to sensitive machinery.

Conclusion

In summary, marine sealing strips are crucial for maintaining the functionality, safety, and efficiency of vessels in the marine industry. Their ability to provide waterproof protection, durability, noise reduction, and energy efficiency makes them indispensable to boat and ship builders, as well as owners. As technology advances, the materials and designs of marine sealing strips will continue to improve, providing even greater protection and performance for marine vehicles. Whether you're an industry professional or a boating enthusiast, understanding the importance of marine sealing strips can greatly enhance your appreciation for the engineering that goes into keeping our vessels safe and seaworthy.

Next: