Aug . 12, 2024 17:12 Back to list

High-Quality Rubber Seal Strips for Aluminum Alloy Doors and Windows from Trusted Manufacturers

The Importance of Aluminum Alloy Door and Window Rubber Seal Strips in Modern Construction

In the contemporary construction landscape, the use of aluminum alloy door and window rubber seal strips has become increasingly prevalent. These components play a critical role in ensuring the durability, energy efficiency, and overall performance of buildings. This article delves into the significance of aluminum alloy seal strips, the manufacturing processes involved, and their multitude of benefits.

Understanding Aluminum Alloy Seal Strips

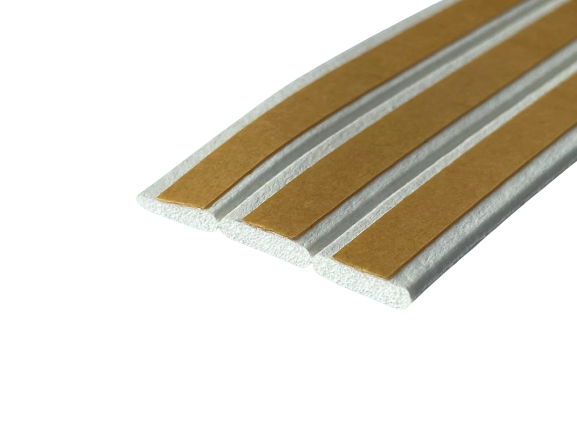

Aluminum alloys are favored for their strength, lightweight nature, and resistance to corrosion. When used in door and window seal strips, they provide a robust framework that enhances the longevity of these fixtures. Rubber seal strips, typically made from materials such as EPDM (Ethylene Propylene Diene Monomer) or silicone, are integrated with aluminum to create a perfect balance of resilience and flexibility.

These seal strips serve multiple functions, primarily acting as barriers against air, water, dust, and noise intrusion. In a world increasingly focused on energy efficiency and sustainability, the significance of these strips cannot be overstated. They help maintain a controlled internal environment, reduce heating and cooling costs, and contribute to overall energy conservation.

Manufacturing Processes

The production of aluminum alloy door and window rubber seal strips involves a combination of advanced technologies and precise engineering. Factories specializing in this sector utilize state-of-the-art equipment to extrude aluminum into desired shapes and dimensions. The extrusion process ensures uniformity, which is crucial for the functionality of seal strips.

Once the aluminum is shaped, rubber sealing material is added through various methods, including co-extrusion and integrated bonding. This ensures a strong adhesion between the aluminum and rubber layers, allowing them to function seamlessly. Quality control measures are pivotal during this stage, as the performance of seal strips depends on the integrity of the bond between materials.

aluminum alloy door and window rubber seal strip factories

Benefits of Using Aluminum Alloy Seal Strips

1. Enhanced Durability Aluminum alloys are inherently resistant to rust and corrosion, making them ideal for outdoor applications. This durability extends the life of door and window installations, translating into significant cost savings for property owners.

2. Improved Energy Efficiency As energy costs continue to rise, the importance of maintaining an energy-efficient building becomes increasingly critical. Properly sealed doors and windows can minimize air leaks, thus reducing the need for excessive heating or cooling.

3. Noise Reduction The integration of rubber seal strips with aluminum frames effectively dampens sound transmission. This feature is particularly beneficial in high-traffic urban areas or places where noise pollution is a concern.

4. Versatility in Design Aluminum alloy seal strips can be customized to fit various design aesthetics and functional requirements. Their sleek appearance complements modern architectural styles while also providing outstanding functionality.

5. Environmental Considerations The longevity and recyclability of aluminum make it a sustainable choice in construction. Using aluminum alloy seal strips supports green building initiatives and aligns with eco-friendly practices.

Conclusion

In summary, aluminum alloy door and window rubber seal strips are indispensable in modern construction. They not only enhance the overall functionality of buildings but also contribute to energy efficiency, durability, and aesthetic appeal. With advancements in manufacturing technology, the quality and effectiveness of these seal strips continue to improve, making them a wise investment for architects, builders, and homeowners alike. As the demand for sustainable and efficient building practices grows, so too will the reliance on high-quality aluminum alloy seal strips, leading the way towards a more resilient and energy-efficient future.