Aug . 03, 2024 02:40 Back to list

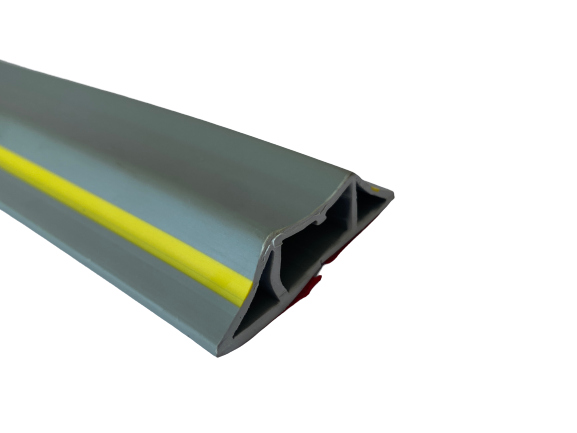

High-Quality Rubber Sealing Strips Designed for Enhanced Car Door Insulation and Durability

The Importance of ODM Rubber Sealing Strips for Car Doors

When it comes to automotive design and manufacturing, every component plays a crucial role in ensuring the vehicle's efficiency, safety, and comfort. One such often-overlooked component is the rubber sealing strip for car doors, particularly those designed under Original Design Manufacturer (ODM) specifications. These sealing strips serve not only functional purposes but also enhance the overall experience of owning and driving a vehicle.

What are ODM Rubber Sealing Strips?

ODM rubber sealing strips are custom-designed components that are produced according to specific requirements set by automotive manufacturers. Unlike Off-The-Shelf (OTS) products, ODM solutions provide tailored options that align seamlessly with the design and functionality of the vehicle. This custom approach allows for greater flexibility and precision in achieving the desired characteristics, such as durability, flexibility, and resistance to environmental stressors.

Key Functions of Rubber Sealing Strips

Rubber sealing strips installed in car doors serve several essential functions

1. Water Resistance One of the primary purposes of sealing strips is to prevent water ingress. These strips create a tight seal when the door is closed, protecting the interior from rain and moisture. This is especially critical in regions prone to heavy rainfall, where water damage can severely impact the vehicle's interior and electronic systems.

2. Sound Insulation A well-designed rubber sealing strip contributes to sound insulation within the vehicle. It minimizes external noise, creating a quieter cabin environment, which enhances the overall driving experience. This is particularly important for luxury vehicles where cabin comfort is a key selling point.

odm rubber sealing strip for car doors

3. Vibration Dampening Cars are exposed to vibrations from the road, which can lead to wear and tear over time. Rubber sealing strips help absorb some of these vibrations, protecting the vehicle’s structural integrity and reducing stress on various components.

4. Thermal Insulation These strips also play a role in maintaining the cabin temperature. A good seal can help keep warm air inside during winter months and repel hot air in the summer, promoting energy efficiency and comfort.

5. Aesthetic Appeal Beyond functionality, ODM rubber sealing strips can be designed to complement the vehicle's aesthetics. They can be produced in various colors and finishes, allowing manufacturers to maintain brand identity and enhance the vehicle's overall appearance.

The Manufacturing Process

The production of ODM rubber sealing strips involves several steps. First, manufacturers collaborate with automotive designers to understand their specific requirements and constraints. Once the design is finalized, the selection of rubber compounds that fulfill the required properties such as elasticity, durability, and temperature resistance is crucial.

The manufacturing process includes mold creation, where the rubber is shaped according to the design specifications. Quality control measures are then implemented to ensure that each strip meets standards for performance and longevity. This meticulous attention to detail guarantees that the sealing strips will function effectively throughout the vehicle's lifespan.

Conclusion

In summary, ODM rubber sealing strips for car doors are vital components that contribute significantly to the vehicle's performance and passenger comfort. They play a multi-faceted role, from ensuring water resistance and sound insulation to providing aesthetic appeal. As automotive technologies continue to evolve, the demand for high-quality, custom-designed sealing solutions will only increase, making ODM rubber sealing strips an integral part of modern automotive engineering. Investing in high-quality sealing strips is not just a matter of compliance but rather an essential component of creating vehicles that meet consumer expectations for quality and reliability.