Aug . 15, 2024 17:58 Back to list

High-Quality Silicone Rubber Seal Strips for Oven Door Manufacturing and Custom Solutions

The Importance of Silicone Rubber Seal Strips for Oven Doors

In the world of kitchen appliances, the oven plays a central role in meal preparation and cooking. A key component that ensures the oven functions efficiently and safely is the silicone rubber seal strip. These strips not only enhance the performance of ovens but also contribute to energy efficiency and safety in the kitchen environment. This article explores the significance of silicone rubber seal strips for oven doors, discussing their properties, manufacturing processes, and benefits.

Understanding Silicone Rubber

Silicone rubber is a versatile material known for its exceptional heat resistance, flexibility, and durability. Unlike traditional rubber, silicone can withstand high temperatures without degrading, making it an ideal choice for applications in ovens, where temperatures can often reach over 500°F (260°C). The resilience of silicone rubber ensures that it maintains its shape and integrity even under extreme conditions, providing a long-lasting solution for oven doors.

Manufacturing Process of Silicone Rubber Seal Strips

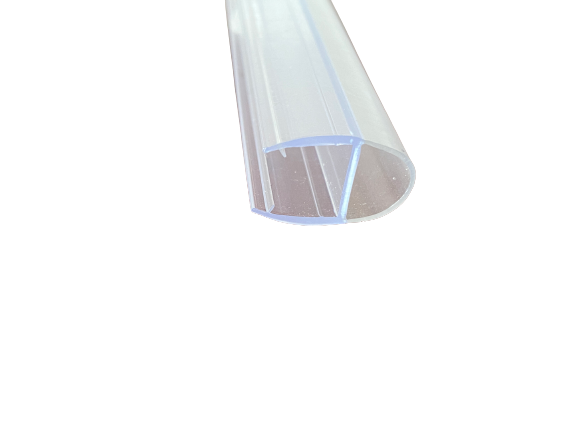

The production of silicone rubber seal strips involves several stages, beginning with the formulation of silicone compounds. Manufacturers combine silicone polymers with additives to enhance properties like heat resistance and tensile strength. This mixture is then molded into the desired shape using compression or injection molding techniques.

After molding, the strips undergo a curing process, which cross-links the polymer chains to increase their durability and elasticity. This final step is critical, as it transforms the raw material into a robust, heat-resistant product suitable for high-temperature environments. Quality control measures ensure that each strip meets stringent industry standards before being shipped to manufacturers for installation in ovens.

silicone rubber seal strip for oven door factory

Benefits of Silicone Rubber Seal Strips

1. Energy Efficiency One of the most significant advantages of silicone rubber seal strips is their ability to create a tight seal around the oven door. This seal minimizes heat loss during cooking, allowing ovens to maintain consistent temperatures and ultimately reducing energy consumption. As a result, not only do consumers save on utility bills, but they also contribute to environmental sustainability.

2. Enhanced Safety Silicone rubber seal strips help to prevent hot air from escaping the oven, reducing the risk of burns when opening the door. Furthermore, a well-sealed oven minimizes the chances of food contamination, as it prevents external particles and odors from entering the cooking chamber.

3. Durability and Longevity Unlike traditional foam or felt seals, silicone rubber withstands wear and tear better and does not degrade over time. This ensures that homeowners do not have to frequently replace seal strips, saving both time and money.

4. Versatility Silicone rubber seal strips are not only used in ovens but can also be applied in various other appliances, including refrigerators, dishwashers, and microwaves. This versatility makes silicone a popular choice among manufacturers and appliance designers.

Conclusion

Silicone rubber seal strips are an integral part of any oven design, enhancing performance and safety while promoting energy efficiency. Their remarkable properties make them ideal for high-temperature environments, providing a long-lasting solution for sealing oven doors. As consumers become increasingly aware of energy efficiency and safety in kitchen appliances, the demand for high-quality silicone rubber seal strips will continue to grow, driving innovation in manufacturing processes and designs. For oven manufacturers, investing in silicone rubber seal strips is not just a matter of compliance, but a commitment to quality and customer satisfaction.