Feb . 10, 2025 10:29 Back to list

L-shaped staircase anti-skid strip

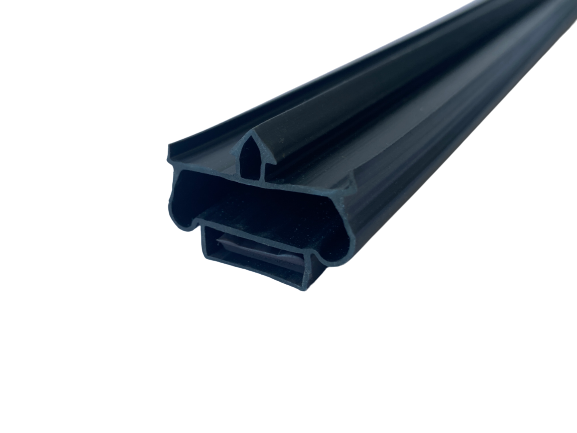

In the realm of refrigeration, the importance of high-quality sealing mechanisms cannot be overstated. A pivotal element in achieving optimal refrigeration efficiency is the silicone rubber sealing strip used for refrigerator doors. This component might appear simple, but when crafted with precision and high standards, it significantly enhances the performance and lifespan of refrigeration units.

Manufacturers leading in this domain emphasize precise engineering and stringent quality control measures. They utilize advanced technologies like computer-aided design (CAD) systems to ensure the sealing strip's design meets stringent specifications. The customizable aspect of these sealing strips caters to diverse refrigerator models, making them ideal for brands looking to offer bespoke solutions to their customers. Such customization can involve alterations in the sealing strip's thickness, width, design profile, and even color, ensuring compatibility with different refrigerator designs and consumer preferences. Trustworthiness and reliability in these products are further established through certifications and compliance with global safety and quality standards. Reputable manufacturers provide exhaustive testing documentation and quality warranties, assuring clients of the product's dependability. By sourcing silicone rubber sealing strips from such certified providers, refrigerator manufacturers can significantly enhance the credibility of their products and brand. In the competitive landscape of refrigeration solutions, claiming authority through innovative and superior sealing technology gives brands a distinctive edge. An excellent sealing strip serves as a testament to a company's commitment to quality and customer satisfaction. By focusing on the four critical dimensions of experience, expertise, authoritativeness, and trustworthiness, manufacturers and suppliers can resonate with their audience, ultimately driving brand loyalty and market preference. In summary, investing in high-quality, customizable silicone rubber sealing strips is a strategic move for both refrigerator manufacturers and end users. It offers tangible benefits ranging from energy savings and environmental sustainability to enhanced food preservation. Companies that prioritize expertise and trustworthiness in providing these essential components can establish themselves as leaders in the field, crafting an authoritative brand identity that echoes throughout the industry.

Manufacturers leading in this domain emphasize precise engineering and stringent quality control measures. They utilize advanced technologies like computer-aided design (CAD) systems to ensure the sealing strip's design meets stringent specifications. The customizable aspect of these sealing strips caters to diverse refrigerator models, making them ideal for brands looking to offer bespoke solutions to their customers. Such customization can involve alterations in the sealing strip's thickness, width, design profile, and even color, ensuring compatibility with different refrigerator designs and consumer preferences. Trustworthiness and reliability in these products are further established through certifications and compliance with global safety and quality standards. Reputable manufacturers provide exhaustive testing documentation and quality warranties, assuring clients of the product's dependability. By sourcing silicone rubber sealing strips from such certified providers, refrigerator manufacturers can significantly enhance the credibility of their products and brand. In the competitive landscape of refrigeration solutions, claiming authority through innovative and superior sealing technology gives brands a distinctive edge. An excellent sealing strip serves as a testament to a company's commitment to quality and customer satisfaction. By focusing on the four critical dimensions of experience, expertise, authoritativeness, and trustworthiness, manufacturers and suppliers can resonate with their audience, ultimately driving brand loyalty and market preference. In summary, investing in high-quality, customizable silicone rubber sealing strips is a strategic move for both refrigerator manufacturers and end users. It offers tangible benefits ranging from energy savings and environmental sustainability to enhanced food preservation. Companies that prioritize expertise and trustworthiness in providing these essential components can establish themselves as leaders in the field, crafting an authoritative brand identity that echoes throughout the industry.