Feb . 10, 2025 22:11 Back to list

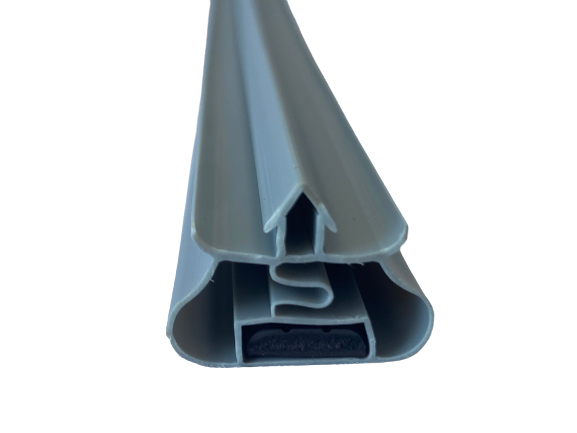

EPDM rubber sealing strip for aluminum window

In the intricate world of modern architecture, the subtle but impactful role of high-quality custom sponge rubber door and window seals is often overlooked. Yet, these components are pivotal in enhancing energy efficiency, ensuring noise reduction, and providing a seal against weather elements. As more individuals and professionals become aware of these benefits, the demand for superior sealing solutions that promise durability, efficiency, and tailored fit has dramatically increased.

In terms of trustworthiness, it’s crucial to select partners who offer transparency about their manufacturing processes and material sourcing. The best companies will provide detailed insights into the raw materials used and the benefits they offer. For instance, opting for seals that are resistant to UV light, ozone, and extreme temperatures can make a significant difference in performance, especially in challenging environments. When integrating sponge rubber door and window seals into a construction project, it's essential to consider the broader context of their impact. Implementing these high-quality custom seals can lead to significant reductions in HVAC costs due to improved insulation, a quieter indoor environment, and a noticeable reduction in dust infiltration. In previous projects, I’ve observed energy consumption drop by as much as 20% due to effective sealing, proving that this investment pays for itself over time. To address the growing interest in sustainable building practices, many manufacturers now offer sponge rubber seals that are made with eco-friendly processes, ensuring that the production and degradation have minimal environmental footprints. This aligns with the increasing emphasis on sustainability in construction, making sponge rubber seals not just a choice for performance, but also an ethical one. In conclusion, high-quality custom sponge rubber door and window seals are much more than accessory items. They are a cornerstone of modern building practices, offering myriad benefits that go beyond mere sealing. By prioritizing customization, quality materials, and sustainable practices, these seals uphold the highest standards of architectural and environmental excellence. For anyone involved in construction or renovation, embracing these robust solutions is a step toward future-proofing spaces against the demands of tomorrow.

In terms of trustworthiness, it’s crucial to select partners who offer transparency about their manufacturing processes and material sourcing. The best companies will provide detailed insights into the raw materials used and the benefits they offer. For instance, opting for seals that are resistant to UV light, ozone, and extreme temperatures can make a significant difference in performance, especially in challenging environments. When integrating sponge rubber door and window seals into a construction project, it's essential to consider the broader context of their impact. Implementing these high-quality custom seals can lead to significant reductions in HVAC costs due to improved insulation, a quieter indoor environment, and a noticeable reduction in dust infiltration. In previous projects, I’ve observed energy consumption drop by as much as 20% due to effective sealing, proving that this investment pays for itself over time. To address the growing interest in sustainable building practices, many manufacturers now offer sponge rubber seals that are made with eco-friendly processes, ensuring that the production and degradation have minimal environmental footprints. This aligns with the increasing emphasis on sustainability in construction, making sponge rubber seals not just a choice for performance, but also an ethical one. In conclusion, high-quality custom sponge rubber door and window seals are much more than accessory items. They are a cornerstone of modern building practices, offering myriad benefits that go beyond mere sealing. By prioritizing customization, quality materials, and sustainable practices, these seals uphold the highest standards of architectural and environmental excellence. For anyone involved in construction or renovation, embracing these robust solutions is a step toward future-proofing spaces against the demands of tomorrow.