Feb . 10, 2025 12:43 Back to list

L-shapedanti-skid PVCrubberstrip staircase opening

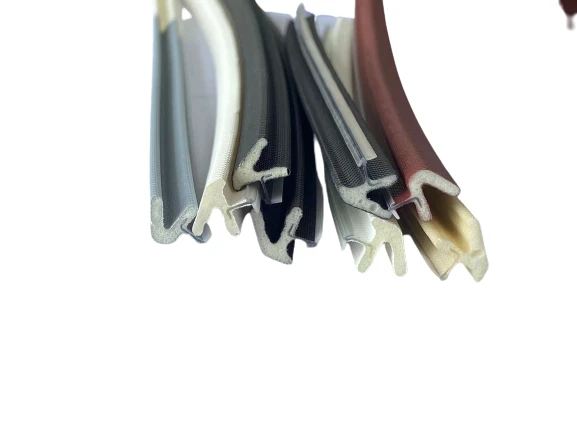

In the vast arena of door seals, the EPDM composite sponge variant has emerged as a frontrunner, blending unparalleled versatility and top-tier performance. Perfectly tailored to meet diverse needs, this high-quality door seal balances efficiency with durability, promising not only a snug fit but also an extended lifespan.

What truly sets them apart is not just the material's intrinsic qualities, but the comprehensive understanding of application needs demonstrated by manufacturers. Thorough analysis and ongoing research into the propensities of EPDM enable the creation of seals that address specific operational challenges while maximizing aesthetic integration. This knowledge, blended with innovative design, leads to practical, reliable solutions that cater to today's demanding architectural and industrial standards. Trustworthiness in this domain is underpinned by client experiences. For professionals who have incorporated these seals into their projects, the feedback tends to highlight the seals' consistent performance and ease of installation. Furthermore, bespoke customer service enhances the user experience, allowing for seamless integration and prompt resolutions to any query or requirement. In the context of sustainability, EPDM composite sponge door seals represent a forward-thinking choice. Their long lifespan coupled with minimal maintenance needs substantially lowers environmental impact compared to more easily degradable materials. Such eco-friendly considerations align with growing global emphasis on sustainable building materials and practices. Leveraging a long-standing reputation built on results, EPDM composite sponge door seals continue to be an integral component of efficient building and vehicle systems worldwide. Investing in such products is strategically sound, attesting to a commitment to quality, performance, and customer satisfaction that stands the test of time.

What truly sets them apart is not just the material's intrinsic qualities, but the comprehensive understanding of application needs demonstrated by manufacturers. Thorough analysis and ongoing research into the propensities of EPDM enable the creation of seals that address specific operational challenges while maximizing aesthetic integration. This knowledge, blended with innovative design, leads to practical, reliable solutions that cater to today's demanding architectural and industrial standards. Trustworthiness in this domain is underpinned by client experiences. For professionals who have incorporated these seals into their projects, the feedback tends to highlight the seals' consistent performance and ease of installation. Furthermore, bespoke customer service enhances the user experience, allowing for seamless integration and prompt resolutions to any query or requirement. In the context of sustainability, EPDM composite sponge door seals represent a forward-thinking choice. Their long lifespan coupled with minimal maintenance needs substantially lowers environmental impact compared to more easily degradable materials. Such eco-friendly considerations align with growing global emphasis on sustainable building materials and practices. Leveraging a long-standing reputation built on results, EPDM composite sponge door seals continue to be an integral component of efficient building and vehicle systems worldwide. Investing in such products is strategically sound, attesting to a commitment to quality, performance, and customer satisfaction that stands the test of time.