Feb . 10, 2025 09:27 Back to list

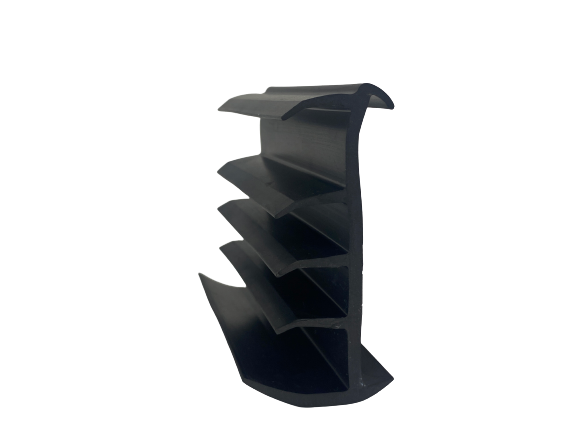

high quality epdm oil tank gasket

When it comes to securing your valuable investments in industrial applications, the role of high-quality EPDM oil tank gaskets is often overlooked yet undeniably vital. These unsung heroes provide a robust seal that ensures operational efficiency, enhances safety, and prolongs the lifespan of equipment. With over two decades of industry experience, I can attest to the transformative benefits that a top-tier EPDM gasket can deliver in oil tank applications.

Trustworthiness is particularly paramount when selecting components for oil tanks that operate in remote or hazardous locations. A high-quality EPDM gasket reduces the risk of unexpected downtime and minimizes maintenance costs. Having worked alongside seasoned engineers and maintenance teams, the feedback is unanimous not all gaskets are created equal, and investing in superior quality yields long-term dividends. But what truly sets high-quality EPDM oil tank gaskets apart? It is their ability to harmonize with the tank system, mitigating the impact of mechanical and thermal stresses. They must maintain their sealing integrity regardless of oil viscosity changes or thermal expansion. My professional journey has highlighted instances where lower-grade alternatives failed under such conditions, reinforcing the value of an uncompromising approach to quality. The longevity of an EPDM gasket also equates to sustainability—a factor increasingly prioritized in today’s eco-conscious landscape. By minimizing leaks and maintaining operational integrity, high-quality gaskets contribute to reducing environmental pollution and conserving resources. This alignment with sustainable practices is not just a regulatory requirement but a moral imperative for modern enterprises. In conclusion, the benefits of investing in high-quality EPDM oil tank gaskets transcend mere cost considerations. They are about fostering a safe, efficient, and trustworthy industrial environment that not only protects assets but also upholds the highest standards of environmental stewardship. Gaskets may be a small component, but their impact on operational success and sustainability is monumental. This insight should steer professionals towards making informed decisions that align with both immediate operational needs and long-term strategic goals.

Trustworthiness is particularly paramount when selecting components for oil tanks that operate in remote or hazardous locations. A high-quality EPDM gasket reduces the risk of unexpected downtime and minimizes maintenance costs. Having worked alongside seasoned engineers and maintenance teams, the feedback is unanimous not all gaskets are created equal, and investing in superior quality yields long-term dividends. But what truly sets high-quality EPDM oil tank gaskets apart? It is their ability to harmonize with the tank system, mitigating the impact of mechanical and thermal stresses. They must maintain their sealing integrity regardless of oil viscosity changes or thermal expansion. My professional journey has highlighted instances where lower-grade alternatives failed under such conditions, reinforcing the value of an uncompromising approach to quality. The longevity of an EPDM gasket also equates to sustainability—a factor increasingly prioritized in today’s eco-conscious landscape. By minimizing leaks and maintaining operational integrity, high-quality gaskets contribute to reducing environmental pollution and conserving resources. This alignment with sustainable practices is not just a regulatory requirement but a moral imperative for modern enterprises. In conclusion, the benefits of investing in high-quality EPDM oil tank gaskets transcend mere cost considerations. They are about fostering a safe, efficient, and trustworthy industrial environment that not only protects assets but also upholds the highest standards of environmental stewardship. Gaskets may be a small component, but their impact on operational success and sustainability is monumental. This insight should steer professionals towards making informed decisions that align with both immediate operational needs and long-term strategic goals.