Feb . 10, 2025 20:17 Back to list

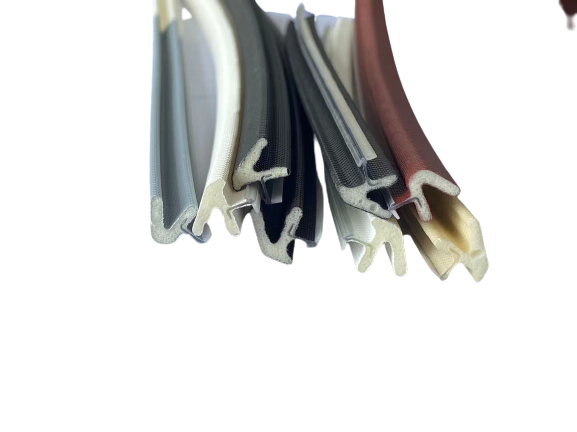

EPDM rubber sealing strip for aluminum window

High quality rubber seals for plastic steel doors and windows are crucial components in the construction industry, serving the vital function of ensuring energy efficiency, noise reduction, and overall comfort in residential and commercial buildings. Rubber seals act as barriers against various environmental factors such as moisture, wind, and dust, thus maintaining the interior conditions of a space consistent and comfortable. Here’s a comprehensive look into why choosing high-quality rubber seals is indispensable.

Beyond performance, using high-quality rubber seals contributes significantly to energy efficiency. Poor sealing can lead to substantial heat loss during winter or heat gain during summer, forcing HVAC systems to overcompensate, which elevates energy costs and increases environmental impact. Seals made with high-precision engineering and robust materials form effective barriers against heat transfer, optimizing insulation properties and resulting in lower energy consumption and bills. The industry recognizes that achieving peak building performance extends beyond mere installation—maintenance of these seals is paramount. Trustworthiness in a manufacturer or supplier is thus an important aspect, ensuring that the seals not only meet specifications but also have certifications and guarantees that back up their claims. Brands that provide extended warranties are often indicative of high trust in their product's durability and performance. For builders, suppliers, and end-users alike, establishing a reliable, authoritative source for high-quality rubber seals is crucial. Working with manufacturers who have a proven track record and peer-acknowledged expertise ensures that the products sourced possess the necessary certifications and standards compliance. In conclusion, the integration of high-quality rubber seals in plastic steel doors and windows is not merely a choice, but an investment into the efficacy, efficiency, and long-term performance of a building. By leveraging a professional approach when selecting and maintaining these components, stakeholders can significantly enhance the sustainability and comfort of their environments, staying aligned with modern demands for energy and cost-effective building solutions. Through rigorous quality control and expert consultation, the promise of optimized building applications becomes not only attainable but a standard in modern construction and design practices.

Beyond performance, using high-quality rubber seals contributes significantly to energy efficiency. Poor sealing can lead to substantial heat loss during winter or heat gain during summer, forcing HVAC systems to overcompensate, which elevates energy costs and increases environmental impact. Seals made with high-precision engineering and robust materials form effective barriers against heat transfer, optimizing insulation properties and resulting in lower energy consumption and bills. The industry recognizes that achieving peak building performance extends beyond mere installation—maintenance of these seals is paramount. Trustworthiness in a manufacturer or supplier is thus an important aspect, ensuring that the seals not only meet specifications but also have certifications and guarantees that back up their claims. Brands that provide extended warranties are often indicative of high trust in their product's durability and performance. For builders, suppliers, and end-users alike, establishing a reliable, authoritative source for high-quality rubber seals is crucial. Working with manufacturers who have a proven track record and peer-acknowledged expertise ensures that the products sourced possess the necessary certifications and standards compliance. In conclusion, the integration of high-quality rubber seals in plastic steel doors and windows is not merely a choice, but an investment into the efficacy, efficiency, and long-term performance of a building. By leveraging a professional approach when selecting and maintaining these components, stakeholders can significantly enhance the sustainability and comfort of their environments, staying aligned with modern demands for energy and cost-effective building solutions. Through rigorous quality control and expert consultation, the promise of optimized building applications becomes not only attainable but a standard in modern construction and design practices.