Nov . 25, 2024 21:37 Back to list

high quality sealing strip for gaps in photovoltaic solar panels

High-Quality Sealing Strips for Gaps in Photovoltaic Solar Panels

As the world increasingly shifts towards renewable energy sources, solar energy has emerged as a leading contender in sustainable power generation. However, the efficiency and longevity of photovoltaic (PV) solar panels are critical for maximizing their benefits. One major concern in the performance of solar panels is the presence of gaps, which can lead to several issues, including reduced energy generation, water infiltration, and damage to the electrical components. To address these challenges, the implementation of high-quality sealing strips is essential.

Understanding the Importance of Sealing Strips

Gaps in solar panels can occur due to manufacturing tolerances, thermal expansions, and contractions caused by environmental changes. These gaps may seem negligible, yet they can significantly affect the performance of the solar system. High-quality sealing strips are designed to fill these gaps, providing a barrier against moisture, dust, and other environmental factors that could compromise the integrity of the solar panels.

Sealing strips play a pivotal role in maintaining the long-term durability of solar panels. Poor sealing can lead to water ingress, which may cause corrosion of the electrical components, create hotspots, and ultimately lead to panel failure. By using high-quality sealing materials, manufacturers and installers can ensure that solar panels remain watertight and protected from external elements, thus enhancing their overall lifespan.

Material Choices for Sealing Strips

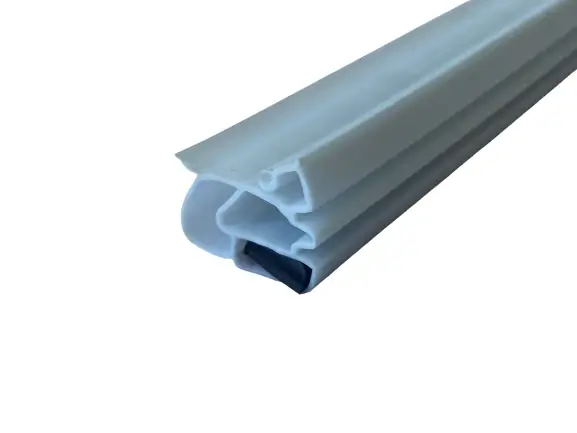

The effectiveness of sealing strips largely depends on the materials used to manufacture them. High-quality sealing strips are typically made from advanced polymers that offer optimal flexibility, durability, and resistance to extreme weather conditions. Common materials include silicone, EPDM (ethylene propylene diene monomer), and neoprene. These materials are selected for their ability to withstand UV radiation, temperature fluctuations, and moisture exposure without degrading over time.

high quality sealing strip for gaps in photovoltaic solar panels

Silicone sealing strips are particularly favored for their excellent adhesion properties and ability to maintain flexibility across a wide temperature range. EPDM is known for its excellent resistance to ozone and UV radiation, making it an ideal choice for outdoor applications. Neoprene, while slightly less UV resistant than EPDM, provides good mechanical strength and resistance to various environmental factors.

Installation Techniques and Best Practices

For ensuring the effectiveness of sealing strips, proper installation techniques are paramount. Before applying the sealing strips, it is crucial to clean the surfaces thoroughly to remove any dust, grease, or previous adhesives. This makes sure that the sealing strip adheres properly, providing a reliable seal.

In addition, it is important to select the right size and thickness of the sealing strip based on the specific gaps that need to be filled. Over-compressing the strip can lead to premature wear, while under-compression may leave gaps vulnerable to infiltration.

Furthermore, regular inspections should be conducted to monitor the condition of the sealing strips. Environmental factors can degrade sealing materials over time, so it is essential to replace any worn or damaged strips promptly to maintain the integrity and efficiency of the solar panels.

Conclusion

In conclusion, high-quality sealing strips are crucial for addressing gaps in photovoltaic solar panels and enhancing their overall performance. By preventing moisture ingress and protecting against environmental damage, these sealing solutions contribute significantly to the longevity and efficiency of solar energy systems. As the industry continues to evolve, the development and implementation of advanced sealing technologies will play a vital role in maximizing the benefits of solar energy, ensuring that this clean energy source remains sustainable and reliable for generations to come. Investing in high-quality sealing strips is not just a choice; it is a commitment to quality, efficiency, and the future of renewable energy.