Dec . 17, 2024 16:34 Back to list

home sealing strip factory

Home Sealing Strip Factory The Unsung Champion of Energy Efficiency

In today's world, where energy conservation and efficiency have become paramount, the importance of home sealing cannot be overstated. One of the most critical components of a well-insulated home is the sealing strip, which plays a vital role in minimizing air leakage, enhancing comfort, and reducing energy costs. Behind the scenes of this essential household solution lies the home sealing strip factory—a hub of innovation, quality control, and sustainable manufacturing practices.

The Importance of Sealing Strips

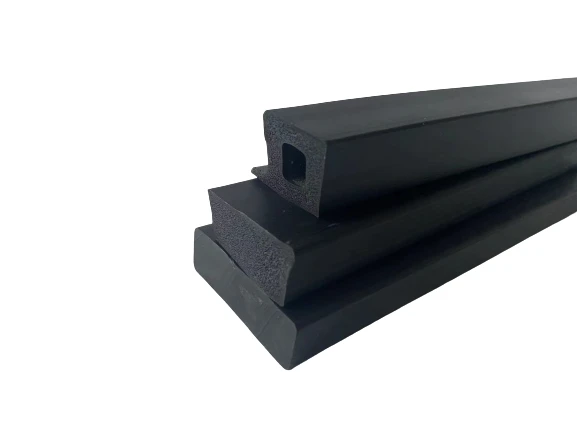

Sealing strips, often made from materials such as rubber, foam, or silicone, are designed to fill gaps and cracks around doors, windows, and other openings in a home. These seemingly small barriers are crucial for maintaining an adequate indoor climate, preventing drafts, and automatically adjusting the thermal barriers of a building. By preventing hot or cold air from escaping, sealing strips contribute significantly to a home’s energy efficiency, which can translate to substantial cost savings on heating and cooling.

Moreover, a well-sealed home reduces the load on heating and cooling systems, thereby extending their lifespan and minimizing maintenance costs. The rise in energy prices has made homeowners increasingly conscious of their consumption, leading to a greater appreciation for products like sealing strips.

The Manufacturing Process

The journey of sealing strips from concept to completion is fascinating. The home sealing strip factory begins with raw materials, primarily rubber, foam, or silicone compounds. Each material is selected for its unique properties—rubber is durable and resilient, foam provides excellent insulation, and silicone is versatile and weather-resistant.

Once the materials are procured, the manufacturing process involves several key steps. First, the raw materials are mixed and prepared for extrusion, where they are shaped into long strips. This is followed by a curing process that gives the sealing strips their final properties, ensuring they are flexible yet robust enough to endure various environmental conditions.

Quality control is a critical aspect of this process. Factories employ stringent testing methods to ensure that each sealing strip meets industry standards for performance and durability. Tests include pressure leakage tests, temperature resistance, and aging tests, ensuring that the final product will maintain its efficacy over time.

home sealing strip factory

Innovations and Sustainability

The home sealing strip factory is not just about producing quality products; it is also at the forefront of innovation. As environmental awareness continues to grow, manufacturers are investing in research and development to create more sustainable sealing solutions. This includes exploring biodegradable materials and developing processes that minimize waste and energy consumption during manufacturing.

One notable innovation is the introduction of self-adhesive sealing strips, which provide a user-friendly installation experience. Homeowners can now easily apply these strips without the need for additional adhesives or tools, making energy efficiency accessible to a wider audience.

The Future of Home Sealing

As the demand for energy-efficient products continues to rise, the home sealing strip factory is poised for growth. Increased awareness of global warming and the push for greener living solutions are propelling innovations in sealing technology. The upcoming trends include advanced smart sealing solutions that automatically adjust to changing temperatures and humidity levels, providing optimal insulation without compromising home comfort.

Moreover, collaboration with eco-friendly suppliers will enable manufacturers to further enhance their sustainability efforts. By adopting circular economy practices, factories can recycle materials and reduce their environmental footprint, contributing positively to the planet.

Conclusion

The home sealing strip factory may not be a household name, but its impact on energy efficiency and comfort in homes is undeniable. By producing high-quality sealing solutions, these factories play a crucial role in minimizing energy consumption and creating a more sustainable future. As technological advancements continue to shape the industry, we can expect innovative products that not only serve practical purposes but also reflect the growing emphasis on environmental responsibility. For homeowners looking to improve their energy efficiency, sealing strips offer a simple yet effective solution, made possible by the dedicated efforts of the manufacturing industry.