Oct . 12, 2024 00:40 Back to list

Household Sealing Strip Production Facility for Efficient Home Insulation Solutions

The Significance of Household Sealing Strip Factories in Modern Manufacturing

In recent years, the demand for household sealing strips has surged, driven by an increased awareness of energy efficiency and the need for improved comfort in residential spaces. Sealing strips play a crucial role in ensuring that homes remain insulated, preventing drafts and moisture from entering. As a result, the significance of household sealing strip factories has become more pronounced in modern manufacturing environments. This article explores the importance of these factories, the manufacturing process, and the innovations shaping the industry.

Understanding Household Sealing Strips

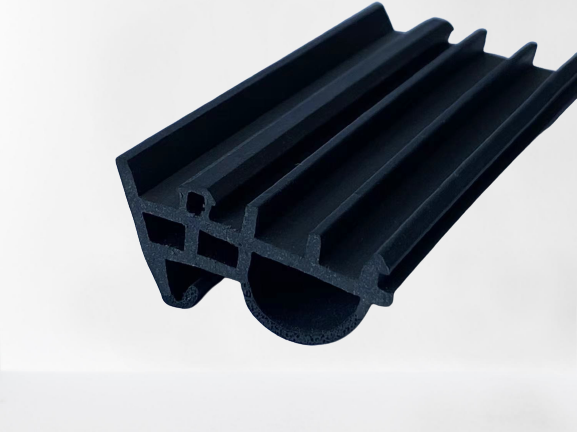

Household sealing strips are versatile components made from various materials such as rubber, foam, and vinyl. They are designed to seal gaps around doors, windows, and other entry points in a home. By effectively sealing these areas, they help maintain indoor temperatures, reduce energy costs, and enhance overall comfort. Moreover, they serve as barriers against dust, insects, and noise, adding to the quality of living spaces.

The Role of Factories in Production

Household sealing strip factories are pivotal in producing these essential items in bulk. The manufacturing process typically involves several steps, including material selection, cutting, molding, and quality control. Factories leverage advanced machinery and technology to enhance production efficiency and accuracy. Automation plays a significant role in this process, ensuring that the strips are produced consistently and meet consumer standards.

The supply chain in sealing strip production is also noteworthy. Factories source raw materials from different suppliers, ensuring that only high-quality materials are used in production. This not only boosts the durability of the sealing strips but also contributes to environmental sustainability through the use of eco-friendly materials.

Innovations in the Industry

household sealing strip factory

The sealing strip industry has not remained static; it has embraced innovation to cater to evolving consumer needs. One significant trend is the development of self-adhesive sealing strips, which simplify the installation process. These strips can be easily applied without requiring additional adhesives or tools, making them user-friendly and appealing to a broader market.

Furthermore, manufacturers are increasingly focusing on sustainable practices. The integration of recycled materials in sealing strip production is a growing trend aimed at reducing environmental impact. Consumers are becoming more eco-conscious, and companies that adopt sustainable practices are often more successful in the market.

Another noteworthy innovation is the customization of sealing strips. Factories are now capable of producing strips tailored to specific dimensions and aesthetics, allowing homeowners to choose products that blend seamlessly with their interiors. This customization trend not only meets individual customer needs but also opens new markets for manufacturers.

Economic Impact and Employment

The growth of household sealing strip factories has a notable positive impact on local economies. These factories create jobs, from assembly line workers to engineers and project managers. The skilled workforce contributed to the regional economy, alongside ancillary industries such as transportation and logistics that benefit from the manufacturing processes.

Moreover, as the demand for sealing strips rises globally, these factories can engage in international trade, further bolstering economic growth. Exporting sealing strips can create additional revenue streams and enhance business sustainability in a competitive marketplace.

Conclusion

In conclusion, household sealing strip factories play a vital role in modern manufacturing, addressing essential consumer needs related to energy efficiency, comfort, and sustainability. As the industry continues to evolve through innovation and a focus on eco-friendly practices, these factories will remain integral to the economy and the environment. With the increasing importance of home insulation and energy conservation, the significance of household sealing strip factories is expected to grow, highlighting their pivotal role in shaping the future of residential manufacturing. As we move forward, these factories will not only help improve the quality of living spaces but also contribute positively to the global movement towards sustainable practices.