Dec . 04, 2024 16:36 Back to list

High-Quality Industrial Rubber Rolls for Versatile Applications and Durability

Industrial Rubber Rolls Essential Components for Various Industries

Industrial rubber rolls are integral components widely used across various sectors, including manufacturing, logistics, agriculture, and food processing. These rolls serve multiple purposes and come in an array of specifications tailored to meet the diverse requirements of different applications. The versatility and durability of rubber rolls make them an indispensable part of many industrial processes.

Material Composition and Manufacturing

At the heart of industrial rubber rolls is the material composition. Typically made from natural or synthetic rubber, these rolls are designed to offer a combination of flexibility, strength, and resistance to wear and tear. The manufacturing process involves careful selection of rubber compounds, which can be customized based on the environment in which the rolls will be used. Factors such as temperature, exposure to chemicals, and mechanical stress play a significant role in determining the appropriate rubber formulation.

The production process also incorporates techniques such as extrusion and calendering. Extrusion allows for the creation of rubber rolls in various sizes and shapes, while calendering helps achieve a smooth surface finish, which is often crucial for applications requiring high friction or grip. The quality of the final product is paramount, as industrial rubber rolls must withstand significant stress and provide reliable performance over time.

Applications Across Industries

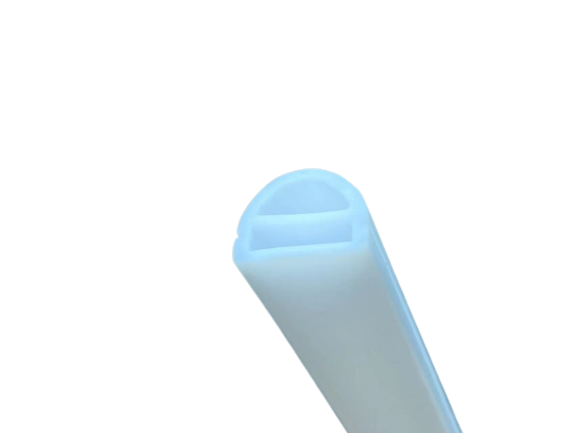

industrial rubber rolls

The applications for industrial rubber rolls are vast. In the manufacturing sector, they are commonly used in conveyor systems where they facilitate the movement of heavy or bulky materials. The non-slip surface of rubber rolls ensures efficient handling, minimizing the risk of material slippage during transit. Their ability to absorb shock also protects both the transported materials and the machinery involved.

In the agriculture industry, rubber rolls are utilized in various machinery, including seeders and harvesters. They help in the even distribution of seeds and improve the efficiency of harvesting processes. The resilience of rubber allows these rolls to operate effectively in rugged environments, ensuring reliability throughout demanding tasks.

The food processing sector also benefits significantly from industrial rubber rolls. They are often found in packaging machines, where they assist in the transportation and handling of food products. Hygiene is critical in this industry; therefore, rubber rolls can be formulated with food-grade materials that comply with health regulations, ensuring that food safety is maintained.

Conclusion

In summary, industrial rubber rolls are crucial components that provide functionality and efficiency across multiple industries. Their material composition, versatile manufacturing techniques, and varied applications highlight their importance in modern industrial operations. As industries continue to evolve, the demand for high-quality rubber rolls is likely to increase, leading to innovations in material science and manufacturing processes. The future of industrial rubber rolls looks promising, with ongoing advancements aimed at enhancing durability, performance, and sustainability. This makes them vital for any industry reliant on reliable machinery and efficient production lines.