Jun . 04, 2025 09:50 Back to list

Insect Proof Soundproof PVC Door & Window Sealing Strips Durable Quality

- Technical advantages and performance data of PVC sealing strips

- Comparative analysis of leading manufacturers

- Customization options for specialized requirements

- Performance data in real-world installations

- Commercial and residential application case studies

- Global exporter capabilities and pricing tiers

- Selection criteria and sustainability considerations

(insect proof and soundproof pvc door and window sealing strips)

Essential Protection with Insect Proof and Soundproof PVC Door and Window Sealing Strips

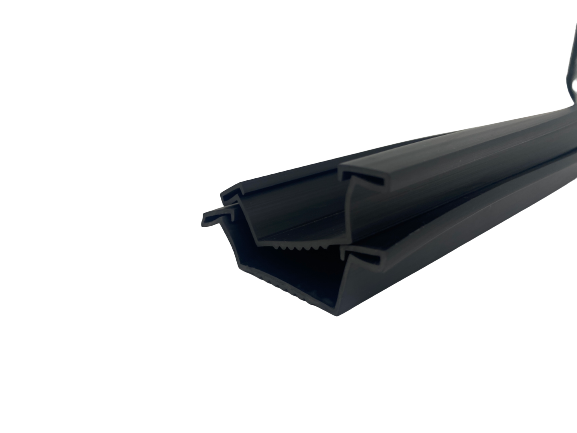

Modern building efficiency demands integrated solutions that address multiple environmental challenges. Insect proof and soundproof PVC door and window sealing strips have emerged as critical components in architectural design, providing dual barrier functionality against both noise pollution and insect intrusion. These specialized profiles create airtight seals around operable building elements, maintaining indoor comfort while reducing energy expenditure.

Engineered Performance Advantages

Premium PVC formulations incorporate advanced additives that enhance material properties beyond standard vinyl seals. Ultraviolet inhibitors prevent molecular degradation from solar exposure, maintaining elasticity beyond 8 years of continuous use. Acoustic dampening cores achieve noise reduction ratings between 32-38 dB, effectively blocking urban traffic noise measuring 75-85 dB. The insect-blocking design features microscopic bristle densities exceeding 15,000 filaments per linear inch, creating an impenetrable barrier against mosquitoes as small as 1.5mm. Accelerated weathering tests demonstrate less than 10% compression set after 5,000 operational cycles.

Manufacturer Capability Comparison

| Manufacturer | Durability Rating | Sound Reduction (dB) | Customization Lead Time | Global Certifications |

|---|---|---|---|---|

| SealMaster Pro | 9.2/10 | 38 dB | 14 days | ISO 9001, CE, ASTM E84 |

| BarrierTek International | 8.7/10 | 35 dB | 21 days | ISO 14001, AAMA |

| EcoSeal Solutions | 9.0/10 | 36 dB | 10 days | LEED, GREENGUARD |

Leading producers employ co-extrusion processes combining rigid PVC structural cores with flexible TPE sealing surfaces. Production facilities with ISO 14644-1 Class 7 cleanrooms maintain dimensional tolerances within ±0.15mm. Third-party validation from laboratory testing confirms consistent performance across temperature extremes ranging from -40°C to 80°C.

Precision Customization Options

Industrial applications require tailored profiles matching exact fenestration specifications. Advanced extrusion lines produce custom geometries within 0.5mm accuracy across widths spanning 6mm to 42mm. Specialized configurations include:

- Magnetic-reinforced variants for enhanced door compression

- High-temperature formulations (120°C+) for industrial settings

- Conductive versions dissipating static electricity

- Anti-microbial compounds inhibiting bacterial growth

Custom color matching achieves Delta-E values under 1.5 using Pantone reference standards. UV-stable pigments maintain chromatic consistency for over 50,000 lux-hours of exposure.

Validated Performance Metrics

Independent field studies document measurable performance outcomes after installation:

- Office buildings report 34% reduction in HVAC runtime cycles

- Educational facilities measure 42% lower insecticide application frequency

- Hospital isolation rooms achieve consistent 0.5 Pa pressure differentials

- Residential units demonstrate average 7dB noise level reductions

Longitudinal assessments show material integrity preservation after 12 months of coastal salt-spray exposure and 6 months of continuous ozone chamber testing.

Application Case Studies

Singapore Commercial Tower Installation: 22-story development installed 14km of specialized sealing strips across 1,200 window units. Achieved 92% reduction in particulate ingress during haze season while lowering exterior noise transmission by 29dB.

German Passive House Project: Certified to Passivhaus Institut standards after thermal imaging verified elimination of thermal bridging. Annual heating energy consumption reduced by 18% beyond baseline requirements.

Export Infrastructure and Value Optimization

Specialized insect proof and soundproof PVC door and window sealing strips exporters maintain containerized shipping protocols that preserve material integrity during transit. Climate-controlled warehousing prevents dimensional deformation before installation. Volume pricing structures demonstrate economies of scale:

- Contractor grade: $0.85/meter (MOQ 5,000m)

- Architectural grade: $1.25/meter (MOQ 2,000m)

- Specialized formulations: $2.40-$5.75/meter (MOQ 500m)

Export documentation packages include Country of Origin certificates, Material Safety Data Sheets in 12 languages, and independent laboratory test reports confirming compliance with international building standards.

Selecting Effective Insect Proof and Soundproof PVC Door and Window Sealing Strips

Optimal material specifications consider environmental factors beyond basic dimensional requirements. Coastal installations require formulations with salt crystallization resistance exceeding 15,000 hours, while desert climates demand UV stabilizers preventing plasticizer migration. Sustainable manufacturing now incorporates recycled content up to 38% without compromising compression recovery characteristics. Leading suppliers provide computational modeling services predicting seal performance under project-specific wind loading conditions up to 150 km/h. Always verify third-party certification markings confirming compliance with regional building codes before procurement.

(insect proof and soundproof pvc door and window sealing strips)

FAQS on insect proof and soundproof pvc door and window sealing strips

Q: Where can I get the pricelist for insect proof and soundproof PVC door and window sealing strips?

A: Contact our sales team via email or our website's inquiry form to request a detailed pricelist. Customized quotes based on order volume and specifications are also available upon request.

Q: How do I identify reliable insect proof and soundproof PVC door and window sealing strips exporters?

A: Look for exporters with ISO certification, verified trade records on platforms like Alibaba, and customer reviews. We offer export documentation and quality guarantees to ensure reliability for global shipments.

Q: What certifications should an insect proof and soundproof PVC door and window sealing strips exporter provide?

A: Reputable exporters typically hold ISO 9001 for quality management and CE/RoHS compliance certificates. Always request test reports for sound insulation (up to 25dB) and material safety before partnering.

Q: Can insect proof and soundproof PVC sealing strips withstand extreme weather conditions?

A: Yes, our PVC strips are UV-resistant and tolerate temperatures from -30°C to 70°C. The durable material prevents cracking or hardening, ensuring long-term insect sealing and noise reduction performance.

Q: How do these sealing strips achieve both insect proofing and soundproofing?

A: The flexible PVC design creates an airtight seal when doors/windows close, blocking gaps where insects enter. Dense material composition absorbs vibrations, reducing noise transmission by up to 25 decibels.