Dec . 17, 2024 14:01 Back to list

Jetty Rubber Fender Solutions for Enhanced Protection and Durability in Marine Environments

Understanding Jetty Rubber Fender Systems A Comprehensive Guide

In the world of maritime construction and marine operations, the importance of efficient protection systems cannot be overstated. One key component that plays a vital role in safeguarding marine structures, vessels, and infrastructure is the jetty rubber fender. Designed to absorb the energy and impact of docking vessels, these rubber fenders are essential for enhancing the safety and longevity of both the dock and the vessels themselves.

What are Jetty Rubber Fenders?

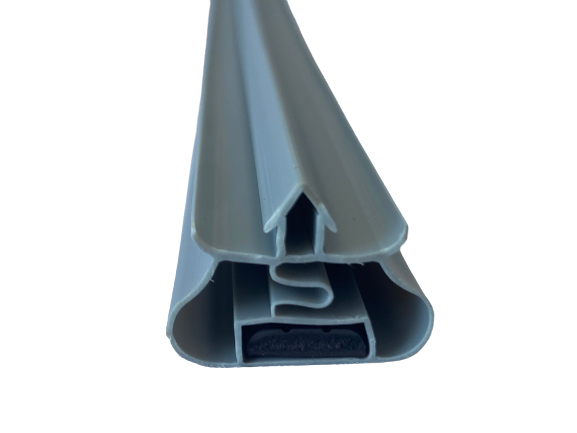

Jetty rubber fenders are engineered marine structures designed to cushion the impact between a vessel and a jetty, dock, or wharf. Made from high-quality rubber, these fenders are capable of absorbing kinetic energy and reducing the stress transmitted to both the vessel and the structure. Their designs come in various shapes and sizes, including cylindrical, square, and special-profiled fenders, each suited for different applications and types of vessels.

Types of Jetty Rubber Fenders

There are several types of jetty rubber fenders available, each serving specific operational requirements. Some of the most common types include

1. D-Type Fenders These fenders are shaped like a “D” and are widely used because of their versatility and robust construction. They can be installed vertically or horizontally on the jetty.

2. Bollard Fenders Designed specifically to withstand heavy tension loads, bollard fenders are often integrated with mooring systems and provide reliable protection against lateral impacts.

3. Cone Fenders These fenders have a tapered design, which allows for effective energy absorption and is particularly suitable for high-energy docks where larger vessels are moored.

4. Square Fenders Square fenders are popular for their simple design and ease of installation. They are frequently utilized in commercial docks and are known for their durable performance.

5. Arch Fenders With a unique arch shape, these fenders distribute the impact loads evenly and are especially effective for larger vessels, such as ferries and bulk carriers.

Key Benefits of Jetty Rubber Fenders

jetty rubber fender

The advantages of implementing jetty rubber fenders in marine environments are numerous

1. Impact Absorption One of the most critical functions of rubber fenders is their ability to absorb impact energy. This absorption minimizes damage to both the fender and the vessel, prolonging the lifespan of both.

3. Versatility Jetty rubber fenders can be fabricated to meet the specific requirements of different marine environments, accommodating vessels of varying sizes and types.

4. Low Maintenance Unlike other marine protection systems made from metal or concrete, rubber fenders require minimal maintenance, making them a practical solution in busy marine settings.

5. Environmentally Friendly Modern rubber fenders are often produced using environmentally friendly materials and processes, reducing their ecological footprint.

Installation and Maintenance

The installation of jetty rubber fenders must be carried out by professionals to ensure proper alignment and secure fastening. Each type of fender will come with specific installation guidelines that outline how to position and fix the fenders to the jetty structure safely.

Maintenance of jetty rubber fenders involves regular inspections to identify signs of wear, tear, or degradation caused by marine elements. Ensuring that the fenders remain in good condition is crucial for their longevity and effectiveness.

Conclusion

In conclusion, jetty rubber fenders are an indispensable component of marine infrastructure designed to protect both vessels and jetties from impacts generated during docking maneuvers. With various types tailored to fit different applications, these fenders provide essential benefits, including impact absorption, cost-effectiveness, and low maintenance. As maritime operations continue to evolve, the significance of reliable jetty rubber fender systems will undoubtedly grow, emphasizing the need for high-quality engineering in maintaining the safety and integrity of our ports and waterways. Investing in the right fender system is not just a smart choice; it is an essential element in ensuring seamless and safe maritime operations.