Aug . 14, 2024 01:23 Back to list

Manufacturers of Rubber Sealing Strips for Aluminum Alloy Doors and Windows Solutions

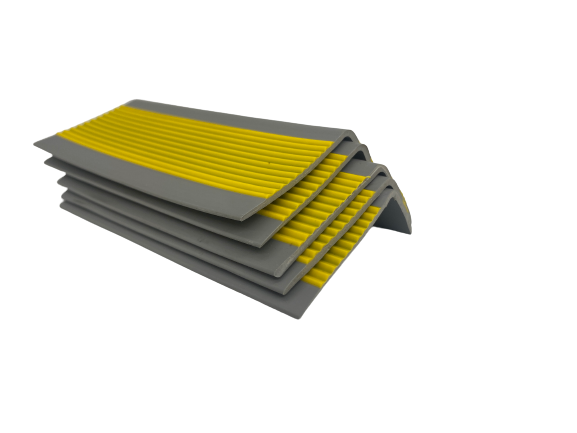

Rubber Sealing Strip for Aluminum Alloy Doors and Windows A Comprehensive Overview

In the realm of modern architecture and construction, the integration of aluminum alloy doors and windows has become increasingly popular due to their aesthetic appeal, durability, and energy efficiency. However, the performance of these installations heavily depends on the quality of their sealing systems. One crucial component often overlooked is the rubber sealing strip, which plays an essential role in ensuring optimal functionality.

Importance of Rubber Sealing Strips

Rubber sealing strips are integral to the structural integrity of aluminum alloy doors and windows. These strips are designed to fill gaps between the frames and the glass or between two surfaces, preventing the intrusion of air, water, and dust. This contributes to improved energy efficiency by minimizing heat loss and reducing the load on heating and cooling systems. Consequently, the right sealing strip can lead to significant energy savings and enhanced comfort within a building.

Furthermore, rubber seals also provide acoustic insulation, making indoor environments quieter by reducing outside noise. This feature is particularly sought after in urban areas where noise pollution can significantly impact quality of life. Additionally, quality rubber sealing strips are resistant to weathering, ensuring longevity and sustained performance despite exposure to UV rays, rain, and changing temperatures.

Types of Rubber Sealing Strips

For aluminum alloy doors and windows, several types of rubber sealing strips are available, each designed to meet specific requirements. Common varieties include

1. EPDM (Ethylene Propylene Diene Monomer) This type is highly durable and resistant to heat, oxidation, and ozone. Its excellent weather resistance makes it ideal for outdoor applications.

rubber sealing strip for aluminum alloy doors and windows manufacturers

2. Silicone Rubber Known for its flexibility and high-temperature resistance, silicone seals are often used in scenarios requiring a high degree of flexibility, such as in sliding doors.

3. Neoprene This type offers a good balance of strength and flexibility, making it suitable for both interior and exterior applications. It is also resistant to oil and chemicals, adding to its versatility.

4. PVC (Polyvinyl Chloride) While not as flexible as rubber options, PVC sealing strips are cost-effective and provide a good barrier against dust and water.

Choosing the Right Manufacturer

When selecting rubber sealing strips for aluminum alloy doors and windows, choosing a reliable manufacturer is crucial. Look for companies that specialize in producing high-quality materials tailored for architectural applications. A reputable manufacturer will provide certifications and test results demonstrating the performance and durability of their products.

Additionally, gaining insights from customer reviews and industry feedback can help identify manufacturers who are known for their reliability and quality. It is also beneficial to inquire about customizable options, as specific architectural designs may require tailored sealing solutions.

Conclusion

Rubber sealing strips are an indispensable component of aluminum alloy doors and windows, playing a vital role in energy efficiency, noise reduction, and overall structural integrity. With various types available, it is essential to choose the right material that meets the specific requirements of your project. By collaborating with reputable manufacturers, builders and homeowners can ensure that their installations not only look aesthetically pleasing but also perform optimally in the long run. As the demand for energy-efficient and durable building solutions continues to rise, the significance of quality rubber sealing strips cannot be overstated.