Oct . 10, 2024 04:00 Back to list

marine fender rubber sealing strip factories

The Importance of Marine Fender Rubber Sealing Strips A Comprehensive Overview

In the maritime industry, protecting vessels, docks, and other marine structures from damage is of utmost importance. One of the critical components in safeguarding these assets is the marine fender rubber sealing strip. These strips are designed to absorb the energy created during berthing operations, reducing the impact on both the vessel and the docking station. In this article, we will explore the significance of marine fender rubber sealing strips, the manufacturing processes involved, and their applications in ensuring maritime safety.

Understanding Marine Fender Rubber Sealing Strips

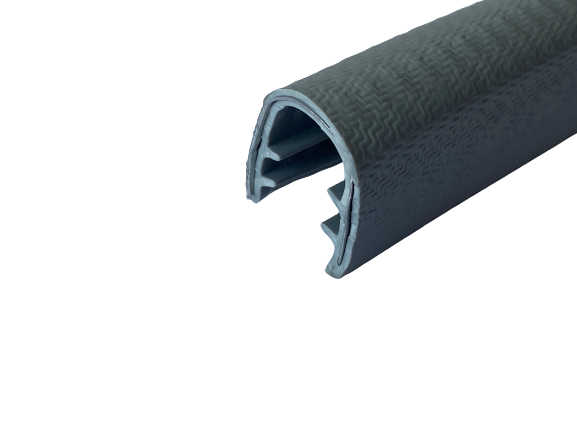

Marine fender rubber sealing strips are essentially protective components made from durable rubber compounds. They serve multiple functions, including shock absorption, protection against water entry, and providing a buffer that prevents contact between vessels and docking facilities. They are integral to various fender systems such as foam-filled fenders, cone fenders, and pneumatic fenders, and contribute significantly to the longevity and effectiveness of these systems.

Manufacturing Process

The production of marine fender rubber sealing strips typically involves several steps. First, manufacturers select high-quality rubber compounds that can withstand harsh marine environments, including UV exposure, saltwater, and extreme temperatures. The rubber is then mixed with additives to enhance its durability and elasticity.

Next, the rubber mixture is shaped into the desired profile using methods such as extrusion or molding. Extrusion is commonly used for producing continuous lengths of sealing strips, while molding is ideal for creating specific shapes and sizes. Once formed, the sealing strips undergo rigorous quality control measures, including tests for tensile strength, flexibility, and resistance to abrasion and chemicals.

After ensuring that the strips meet industry standards, they are cut to length and prepared for packaging. Reputable factories also offer customization options, enabling clients to specify dimensions, shapes, and compounds for their specific needs.

marine fender rubber sealing strip factories

Applications in Maritime Safety

Marine fender rubber sealing strips are employed in a variety of settings across the maritime sector. They are commonly found in ports, harbors, and marinas, where they line the edges of docks and berthing areas. They also play a crucial role in protecting ships during loading and unloading operations, preventing potential harm to both vessels and infrastructure.

Furthermore, these sealing strips contribute to overall safety by reducing the risk of accidents. The cushioning effect provided by the rubber material helps to minimize sudden jolts, which can destabilize cargo or injure dock workers. As a result, proper installation and maintenance of marine fender sealing strips are critical in ensuring that they function effectively over time.

Environmental Considerations

In recent years, there has been an increasing focus on sustainability within the manufacturing industry, including in the production of marine fender rubber sealing strips. Many factories are now adopting eco-friendly practices, such as using recycled materials and reducing waste during the production process. Additionally, research is ongoing to develop rubber compounds that are both high-performing and environmentally responsible.

Conclusion

Marine fender rubber sealing strips are an essential component in the protection of vessels and marine structures. Their ability to absorb impact, prevent water entry, and ensure safe docking operations makes them invaluable in the maritime industry. With improvements in manufacturing processes and a growing emphasis on sustainability, the future of marine fender rubber sealing strips looks promising. As the maritime sector continues to evolve, these sealing strips will remain a critical investment for ports and shipping companies aiming to enhance safety and operational efficiency. By choosing high-quality sealing strips, stakeholders can protect their assets and contribute to the overall integrity of marine operations.