Sep . 28, 2024 18:29 Back to list

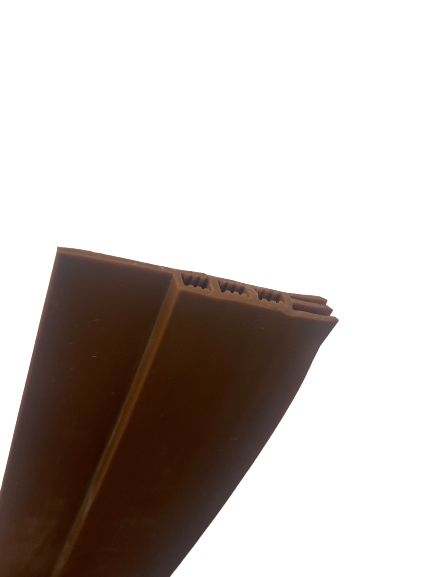

Marine Fender Rubber Sealing Strips for Enhanced Protection and Durability

The Importance of Marine Fender Rubber Sealing Strips

In the world of maritime operations, safety and efficiency are paramount. One of the often-overlooked components that contribute significantly to these aspects is the marine fender rubber sealing strip. These specialized strips play a critical role in protecting both vessels and docks, ensuring smooth operations while minimizing damage during docking and mooring activities.

Understanding Marine Fender Rubber Sealing Strips

Marine fender rubber sealing strips are essential components used in conjunction with marine fenders. These sealing strips are typically made from high-quality, durable rubber, designed to withstand harsh marine environments. By creating a cushion between the vessel and the docking structure, they reduce the impact force during berthing, thus protecting both the ship and the port infrastructure.

The primary function of these sealing strips is to absorb shock and vibrations that occur during the docking process. They act as an additional layer of protection, preventing direct contact between hard surfaces that can lead to damage. This is especially important for large vessels that can exert significant force upon impact due to their size and weight.

Benefits of Using Marine Fender Rubber Sealing Strips

1. Enhanced Protection The sealing strips provide an extra layer of defense, absorbing the energy of impact and dissipating it evenly. This minimizes the risk of structural damage to both the ship and the dock.

2. Durability and Longevity Made from high-quality rubber, these sealing strips are resistant to wear and tear, UV radiation, and harsh environmental conditions like saltwater and extreme temperatures. This ensures they last longer, providing cost-effective solutions in the long run.

3. Improved Safety With effective cushioning, the potential for accidents and injuries is significantly reduced. Workers and crew members can perform their tasks with greater confidence when docking, knowing that the right safety measures are in place.

4. Noise Reduction The rubber material not only absorbs shock but also dampens noise generated during docking. This is especially beneficial for ports located near residential areas, where noise pollution can be an issue.

marine fender rubber sealing strip products

5. Versatility of Use Marine fender rubber sealing strips can be utilized in various marine applications, including harbors, piers, and shipyards. They are suitable for both commercial and recreational vessels, making them versatile tools in marine operations.

Installation and Maintenance

Proper installation of marine fender rubber sealing strips is critical to their functionality. These strips should be fitted correctly along the fender’s surface to ensure they provide the maximum cushioning effect. Regular inspections should also be conducted to identify any wear or damage that may occur over time. Prompt replacement or repair of damaged sealing strips is essential to maintain their protective capabilities.

Maintenance procedures can include cleaning the strips to prevent the build-up of salt or other corrosive materials that can degrade the rubber. Additionally, checking for signs of wear, such as cracks or tears, should be a routine part of dock management.

Advancements and Future Trends

As technology advances, so do the materials and design of marine fender rubber sealing strips. Manufacturers are developing more innovative solutions that enhance performance and sustainability. The incorporation of environmentally friendly materials and designs not only helps in reducing waste but also offers improved functionality.

With the increasing focus on sustainability and environmental protection, future developments may lead to the production of rubber sealing strips that are both effective and eco-friendly. This aligns with global initiatives to reduce the maritime industry’s carbon footprint and promote the use of sustainable materials in marine construction.

Conclusion

Marine fender rubber sealing strips are crucial for ensuring safe and efficient maritime operations. Their role in protecting vessels and docks cannot be overstated. By absorbing shock and minimizing impact, they contribute to the longevity of both the ships and the port facilities. As technology and sustainability practices evolve, these sealing strips will likely become even more critical to the maritime industry, reinforcing the importance of safe docking practices in an increasingly busy and environmentally conscious world. Whether for commercial shipping or recreational boating, the advantages offered by marine fender rubber sealing strips make them indispensable in modern maritime operations.