Oct . 10, 2024 11:57 Back to list

marine fender seals can be customized

Customization of Marine Fender Seals Ensuring Safety and Efficiency in Maritime Operations

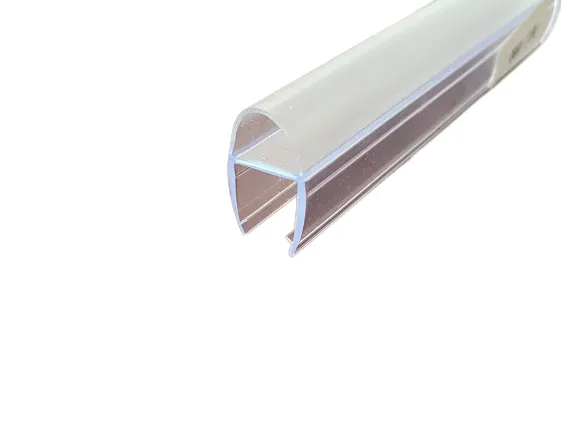

Marine fender seals play a critical role in the maritime industry, providing protection to vessels during docking and berthing. These seals are designed to absorb the kinetic energy of ships as they come into contact with port structures, ensuring that both the vessel and the dock remain unharmed. However, not all marine operations are the same; different vessels have varying sizes, weights, and operational requirements. This is where the customization of marine fender seals becomes essential.

Understanding Marine Fender Seals

Marine fender seals, typically made from durable materials like rubber or polyurethane, are engineered to withstand harsh marine environments. They are an integral part of the fender systems utilized in ports around the world. The primary function of these seals is to offer a cushioning effect when ships are moored, reducing the risk of damage to vessels and docks alike. Given the diverse conditions present in different ports—such as tidal variations, weather conditions, and vessel types—having customizable fender seals can enhance safety and efficiency in marine operations.

The Need for Customization

Customization of marine fender seals is essential for several reasons

1. Variability in Vessel Specifications Vessels differ in size, shape, and weight. A container ship, for instance, has different fendering needs compared to a luxurious cruise liner. Custom seals ensure that each type of vessel is appropriately protected during docking.

2. Port Design and Configuration Each port has unique design features, including dock heights, types of berths, and environmental conditions. Customized fender seals can be tailored to fit the specific requirements of a port’s infrastructure.

3. Performance Requirements Different nautical environments may demand various performance metrics from fender seals. For example, a busy commercial port may require seals that can absorb more energy due to the frequent berthing of large vessels, while a small marina might prioritize softer seals for smaller boats.

4. Compliance with Regulations Different regions may have specific regulations governing maritime safety. Customization allows operators to meet these regulatory requirements effectively.

The Customization Process

The process of customizing marine fender seals generally involves several stages

marine fender seals can be customized

1. Assessment of Requirements This initial phase involves understanding the specific needs of the client, including vessel types, port characteristics, and expected operational conditions.

2. Material Selection Based on the assessment, manufacturers can select the appropriate materials. Factors such as resilience, durability, and resistance to environmental conditions play a crucial role in material choice.

3. Design Engineering Engineers will design the fender seals, considering factors such as the expected impact energy, deflection rates, and overall dimensions. Advanced computer modeling can help visualize the performance of the fender seals in various scenarios.

4. Prototyping and Testing Before full-scale production, prototypes are often created and rigorously tested to ensure that they meet performance standards. This could involve physical testing under real-world conditions.

5. Production and Installation After finalizing the design and passing initial tests, the customized fender seals are manufactured, shipped, and installed in the port’s fendering system.

Benefits of Customized Marine Fender Seals

Investing in customized marine fender seals provides numerous advantages, such as

- Enhanced Protection Customized solutions provide superior protection to both vessels and port structures, reducing maintenance and repair costs over time.

- Improved Efficiency The right fender seals ensure smoother operations during docking, which can lead to faster turnaround times for vessels.

- Longer Lifespan Tailored fender systems created with appropriate materials can withstand unique marine environments, enhancing their longevity compared to standard solutions.

- Increased Safety With better cushioning and energy absorption, customized marine fender seals minimize the risk of accidents and injuries in busy ports.

In conclusion, the customization of marine fender seals is vital for the effective and safe management of maritime operations. By addressing the unique requirements of different vessels and port infrastructures, custom fender seals ensure optimal performance, longevity, and safety in an ever-evolving maritime landscape. Whether for commercial shipping or recreational boating, embracing customization can lead to more efficient and secure maritime operations.