Oct . 30, 2024 16:02 Back to list

marine fender seals can be customized factories

Customizable Marine Fender Seals An Essential Solution for Marine Operations

Marine fenders play a crucial role in ensuring the safety and efficiency of docking procedures across various marine operations. These essential components protect vessels from damage during mooring and berthing, absorbing the impact forces between larger ships and docks or other vessels. However, as with many industrial components, the effectiveness of marine fenders can be significantly enhanced through customization, particularly with seals.

One of the main advantages of customizable marine fender seals is their ability to meet specific operational requirements. Different vessels may have varying sizes, weights, and operational conditions, which means a one-size-fits-all solution often falls short. By tailoring fender seals to match the unique dimensions and characteristics of each vessel, marine operators can ensure optimal performance and protection.

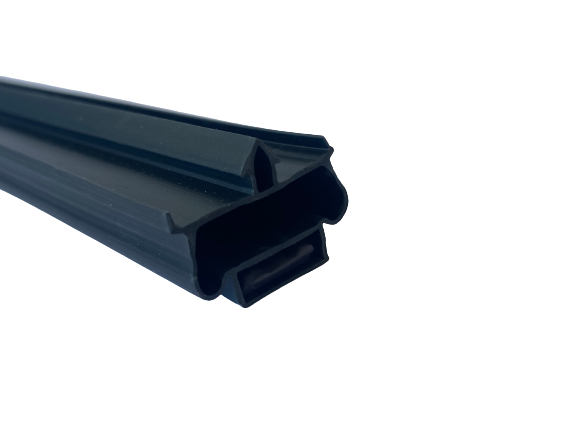

Various factories specialize in the production of custom marine fender seals, offering a range of materials and design options. These factories utilize advanced manufacturing techniques to create seals that can withstand harsh marine environments. Most commonly made from durable polymers such as polyurethane or rubber, these seals are designed to endure exposure to saltwater, UV radiation, and extreme temperatures. The seal's material not only affects its durability but also its compressibility and energy absorption capabilities, making customization vital for performance enhancement.

marine fender seals can be customized factories

Moreover, the design of marine fender seals is just as significant as the material. Factory customization allows for modifications in dimensions, shapes, and profiles, which can cater to specific berthing scenarios. For instance, seals can be designed with varying hardness or thickness to provide the required cushioning effect. Additionally, innovative designs such as contoured or modular seals can be created to fit unusual docking configurations, ensuring that every portion of the docking surface is effectively protected.

Another compelling reason for investing in custom marine fender seals is the potential for cost-effectiveness in the long run. While the initial investment may be higher compared to standard seals, customized solutions can lead to reduced maintenance costs and increased longevity. A well-designed seal minimizes wear and tear, thereby extending the life of both the fender and the vessel itself. This longevity translates into savings on repairs and replacements, making custom seals a financially savvy choice for marine operators.

Furthermore, working with specialized factories enables clients to receive expert consultation throughout the design and manufacturing process. Knowledgeable engineers and designers can provide valuable insights into the best practices for fender seal applications, taking into consideration factors such as load dynamics, environmental conditions, and operational requirements. This collaboration ensures that the final product is not only tailored to specifications but also optimized for maximum efficiency and safety.

In conclusion, customizable marine fender seals represent a critical innovation in marine operations. Their ability to adapt to specific vessel requirements and environmental conditions enhances safety and efficiency at docking stations. As marine industries continue to evolve, the importance of tailored solutions like custom fender seals cannot be overstated. Investing in these products from reliable factories ensures that vessels remain protected and perform at their best, paving the way for safer, more efficient marine operations.