Dec . 21, 2024 15:40 Back to list

marine fender seals can be customized service

Customized Marine Fender Seals Enhancing Safety and Performance in Marine Operations

In the world of maritime logistics and operations, safety and efficiency are of utmost importance. One critical component that contributes to both is the marine fender system, which serves as a protective barrier between vessels and docking structures. Within this realm, the customization of marine fender seals is increasingly becoming a focal point for companies aiming to enhance performance and ensure the safety of their operations.

Understanding Marine Fender Seals

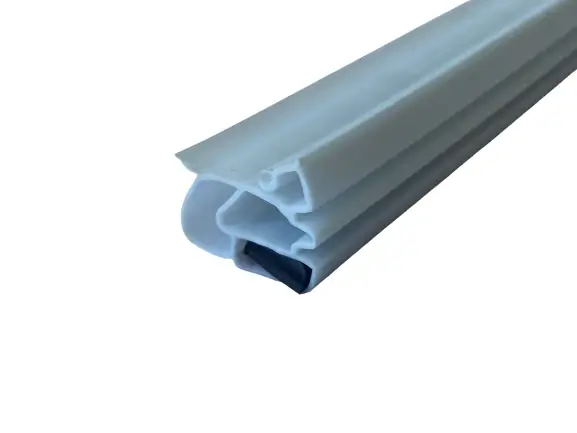

Marine fender seals are designed to protect vessels during berthing and unloading processes. They absorb the energy generated during impacts, thereby mitigating potential damage to both the vessel and the docking infrastructure. The effectiveness of these seals is vital for preventing costly repairs and minimizing downtime. This is why the customization of marine fender seals is more than just an option; it’s a necessity for many marine operations that encounter unique challenges and environments.

The Need for Customization

Every port and marine operation has its distinct characteristics, including the size and type of vessels, tidal variations, environmental conditions, and specific operational requirements. Standard fender seals often fall short in addressing these unique challenges. Customized marine fender seals allow companies to tailor products that fit their specific needs, ensuring greater protection and efficiency.

For instance, a port that regularly handles larger cargo vessels may require seals with higher energy absorption capabilities to withstand more substantial impacts. Conversely, smaller leisure craft may not need the same level of protection but may benefit from lighter, more flexible seals that can easily adapt to changes in tide. By offering customized solutions, manufacturers can help operators optimize performance and extend the lifespan of marine fender systems.

Material Considerations

The choice of materials is crucial when customizing marine fender seals. Various factors, such as exposure to harsh weather conditions, saltwater, and wear and tear, play a significant role in determining the appropriate materials to use. High-quality elastomers, composites, and polyurethane foams are common choices that provide excellent durability and resilience.

marine fender seals can be customized service

Custom manufacturers can also incorporate features like UV resistance, anti-fouling coatings, and enhanced abrasion resistance into their products. These additions not only improve the longevity of the seals but also reduce maintenance requirements, which is critical for busy ports where minimizing downtime is a priority.

Engineering and Design

The engineering and design phase is essential for developing effective customized marine fender seals. Experienced manufacturers utilize advanced computer-aided design (CAD) software and simulation tools to create precise models that adapt perfectly to the unique geometry of the docking area. Collaboration with marine engineers and port authorities ensures that all critical factors are considered, such as load distribution and pressure points.

Moreover, prototypes can be developed and tested under real-world conditions before mass production. This iterative process allows for refinement and ensures that the final product meets all safety and performance standards.

Cost-Effectiveness and Long-Term Value

Investing in customized marine fender seals may initially appear to be a higher upfront cost compared to standard options. However, the long-term benefits far outweigh this investment. Customized seals enhance operational efficiency, reduce maintenance costs, and lead to fewer vessel damages over time. As a result, companies can significantly lower their overall operational expenses while improving their safety records.

Conclusion

In the competitive world of maritime operations, customized marine fender seals offer a crucial advantage. They provide tailored solutions that enhance safety, durability, and overall performance. As the maritime industry continues to evolve, the demand for specialized, high-quality marine fender seals will undoubtedly grow. Companies that prioritize customization not only safeguard their assets but also position themselves for greater success in an ever-changing environment. Ultimately, the combination of innovation, engineering expertise, and a commitment to quality will pave the way for safer and more efficient marine operations around the globe.