Nov . 07, 2024 22:21 Back to list

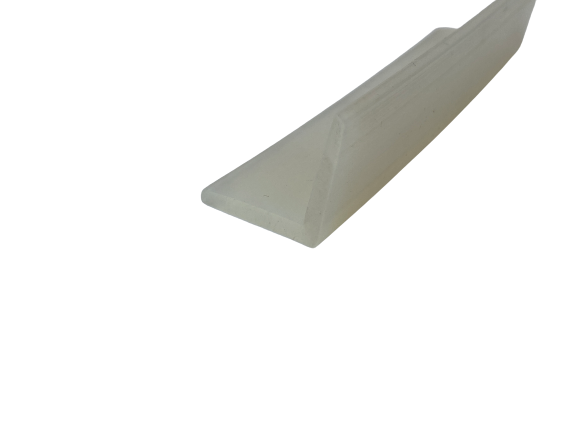

NBR Rubber Plates in Various Thicknesses for Industrial Applications and Custom Solutions

NBR Rubber 1-20mm Rubber Plate The Ideal Choice for Industry and Innovation

In today's fast-paced industrial landscape, the demand for high-performance materials is at an all-time high. One such material that has gained prominence across various sectors is NBR (Nitrile Butadiene Rubber). Known for its excellent resistance to oils, fuels, and various chemicals, NBR rubber plates ranging from 1mm to 20mm in thickness have become increasingly essential in the manufacturing and construction industries. This article delves into the characteristics, applications, and importance of NBR rubber plates, highlighting why they are the preferred choice for many companies.

What is NBR Rubber?

Nitrile rubber, or NBR, is a synthetic rubber that is produced through the copolymerization of acrylonitrile and butadiene. Its unique properties make it an excellent material for applications that demand resistance to oil, gasoline, and other petroleum-based products. The versatile nature of NBR leads to its use in a variety of forms, including sheets, gaskets, seals, and of course, rubber plates.

Characteristics of NBR Rubber Plates

1. Oil and Chemical Resistance One of the primary advantages of NBR rubber plates is their outstanding resistance to oils and chemicals. This makes them ideal for industries dealing with lubricants, petrochemicals, and other corrosive substances.

2. Durability and Strength NBR rubber is known for its high tensile strength and durability. Plates made from NBR can withstand heavy loads and mechanical stress, making them suitable for industrial applications.

3. Temperature Resistance NBR can perform well in a temperature range of approximately -40°C to 120°C, allowing it to function effectively in various environments without significant degradation.

5. Non-Toxic and Safe NBR rubber plates are generally non-toxic, making them safe for use in food processing and medical equipment where contamination is a concern.

nbr rubber 1-20mm rubber plate company

Applications of NBR Rubber Plates

NBR rubber plates serve various purposes across multiple industries

- Automotive Industry In automotive manufacturing, NBR is widely used for gaskets, seals, and fuel line hoses that come into contact with oil and fuel. Its ability to resist wear and tear extends the lifespan of critical components.

- Manufacturing Sector NBR plates are used as flooring materials in factories and warehouses, providing excellent grip and chemical resistance. They also serve as cushioning materials in machinery to reduce vibration and noise.

- Food Processing The food industry relies on NBR for manufacturing conveyor belts and other materials where oil and fats are present. The non-toxic nature of the rubber ensures safety and compliance with health regulations.

- Construction In construction, NBR rubber plates are utilized for padding and insulation, allowing for better thermal efficiency and protection against environmental factors.

Choosing the Right Supplier

When selecting NBR rubber plates, it is vital to choose a reputable company with a proven track record. Companies should ensure that their suppliers adhere to high manufacturing standards and can provide material specifications to meet industry requirements. Reliable suppliers will also offer customization options, such as cutting plates to specific dimensions, ensuring that businesses receive products tailored to their unique needs.

Conclusion

In conclusion, NBR rubber plates measuring between 1mm and 20mm in thickness are a fundamental component across various industries, thanks to their versatility and superior properties. Whether used in automotive, manufacturing, food processing, or construction, their unique characteristics make them a reliable choice. As industries continue to evolve and demand higher standards, the importance of materials like NBR will inevitably grow, positioning them as a cornerstone for future innovations in production and manufacturing. Investing in high-quality NBR rubber plates is not just a choice but a strategic move that can lead to enhanced efficiency and durability in operations.