Dec . 29, 2024 18:27 Back to list

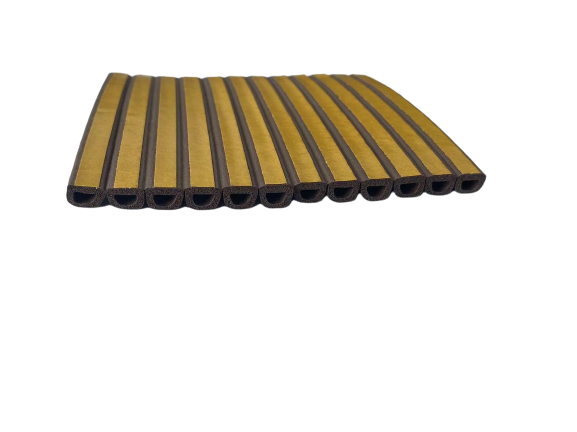

nbr rubber 1-20mm rubber plate factory

NBR Rubber 1-20mm Rubber Plate Factory Quality, Versatility, and Innovation

In the realm of industrial materials, NBR rubber, or nitrile butadiene rubber, stands out for its remarkable properties and versatility. As industries continue to evolve, the demand for high-quality NBR rubber plates, specifically those ranging from 1 to 20mm in thickness, is on the rise. This article explores the significance of NBR rubber plates, examines their manufacturing process, and highlights how factories are meeting the growing needs of various sectors.

Understanding NBR Rubber

NBR rubber is synthesized from the copolymerization of butadiene and acrylonitrile. The unique composition results in a material that offers excellent resistance to oil, fuel, and chemicals, making it ideal for applications in automotive, aerospace, and manufacturing industries. One of the primary advantages of NBR rubber is its ability to withstand a wide range of temperatures, from extreme cold to elevated heat. Additionally, its mechanical strength, durability, and flexibility enable it to perform effectively in demanding environments.

Applications of NBR Rubber Plates

NBR rubber plates with thicknesses from 1mm to 20mm are extensively utilized in various applications

1. Automotive Industry NBR rubber is widely used in gaskets, seals, and hoses due to its oil resistance. These components are critical for maintaining the integrity and performance of automotive systems.

2. Industrial Equipment Machinery and equipment often require anti-vibration mounts and insulation pads made of NBR rubber to minimize noise and vibration. The plates absorb shocks, extending the lifespan of machinery.

3. Construction Sector NBR rubber plates are used as protective mats, flooring solutions, and sealing materials in construction projects. Their robustness ensures longevity, reducing the need for frequent replacements.

4. Medical Applications In the medical field, NBR rubber is utilized for several purposes, including grips for medical devices and equipment, providing a non-slip surface that enhances usability.

The Manufacturing Process

nbr rubber 1-20mm rubber plate factory

The production of NBR rubber plates involves several crucial steps

1. Raw Material Selection Quality starts with the selection of raw materials. Renowned factories source high-grade butadiene and acrylonitrile to ensure superior performance characteristics in the final product.

2. Compounding The selected raw materials are mixed with additives such as fillers, plasticizers, and curing agents to enhance specific properties. This step is crucial to achieving the desired hardness, flexibility, and durability.

3. Molding and Shaping The compounded material is then subjected to molding. It can be cast into sheets of varying thicknesses, ensuring precise dimensions. Advanced machinery enables manufacturers to produce plates with uniform thickness and superior surface finish.

4. Curing Process Curing, or vulcanization, is the process that involves heating the molded rubber to create cross-links between polymer chains. This step is essential for enhancing the strength and resilience of NBR rubber plates.

5. Quality Control Rigorous quality control measures are implemented throughout the manufacturing process. This includes testing for tensile strength, elongation, and chemical resistance to ensure that every plate meets industry standards.

Innovations in NBR Rubber Manufacturing

With the increasing demand for sustainable products, NBR rubber manufacturers are innovating by incorporating eco-friendly practices. This includes recycling scrap materials, using bio-based additives, and improving energy efficiency in production processes.

Additionally, advancements in technology have led to the development of specialized NBR formulations that cater to unique applications. For example, some manufacturers now offer NBR rubber plates with enhanced thermal conductivity or improved electrical insulation properties, expanding the range of possibilities for end-users.

Conclusion

The NBR rubber 1-20mm rubber plate factory plays a pivotal role in supplying industries with essential materials that meet high-performance demands. The unique properties of NBR rubber, combined with innovative manufacturing processes, ensure that these plates not only provide unparalleled durability and resistance to harsh conditions but also adapt to the evolving needs of various sectors. As we advance further into the 21st century, the commitment to quality, sustainability, and innovation will continue to drive the success of NBR rubber manufacturing, making it a cornerstone of modern industrial materials. Whether in automotive applications, industrial settings, or medical environments, NBR rubber plates are undoubtedly an integral component of many critical systems.