Nov . 09, 2024 07:46 Back to list

High-Quality NBR Rubber Sheets 1 to 20mm for Industrial Applications

NBR Rubber Sheets A Comprehensive Overview of the Manufacturer's Offerings

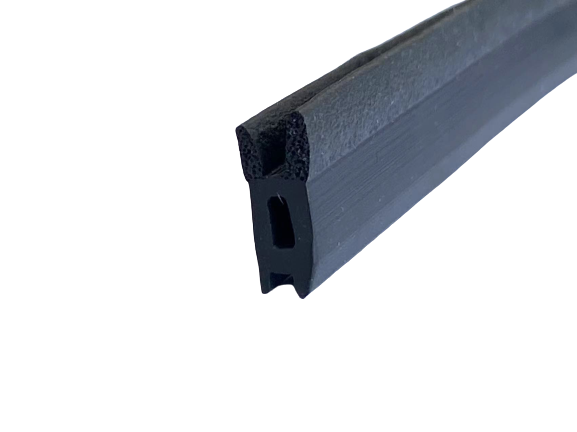

Nitrile Butadiene Rubber (NBR), a popular synthetic rubber, has gained a prominent place in various industries due to its excellent oil, fuel, and abrasion resistance properties. Among its many applications, NBR rubber sheets stand out for their versatility and reliability. This article delves into the characteristics, manufacturing process, and benefits of NBR rubber sheets, focusing on the range of products available from leading manufacturers, specifically in the 1 to 20 mm thickness category.

Understanding NBR Rubber

NBR is a copolymer of acrylonitrile and butadiene, renowned for its excellent resistance to petroleum-based oils and fuels. Its unique chemical structure provides superior durability, making it an ideal material for applications that involve exposure to harsh environments. Whether used in automotive, aerospace, or industrial sectors, NBR rubber is valued for its resilience and longevity.

Features of NBR Rubber Sheets

NBR rubber sheets are available in various thicknesses, with options ranging from 1 mm to 20 mm. This flexibility allows manufacturers to cater to diverse needs and specifications. Some key features of NBR rubber sheets include

1. Oil and Fuel Resistance One of the standout attributes of NBR is its ability to withstand oils and various petrochemical products, making it ideal for gaskets, seals, and seals in automotive applications.

2. Abrasion Resistance NBR rubber sheets exhibit high resistance to wear and tear, making them suitable for industrial applications where friction is a concern.

3. Tensile Strength and Elasticity The rubber provides excellent tensile strength and elongation properties, allowing it to maintain shape under stress while returning to its original form.

4. Temperature Resistance NBR can perform effectively in a variety of temperatures, typically from -30°C to 100°C (-22°F to 212°F), making it a versatile option for different conditions.

5. Chemical Resistance Beyond oil and fuel, NBR rubber also offers good resistance to certain chemicals, contributing to its functionality in various industrial processes.

Manufacturing Process of NBR Rubber Sheets

The manufacturing process of NBR rubber sheets involves several critical steps to ensure high quality and performance

nbr rubber 1~20mm rubber sheet manufacturer

1. Compounding The process begins with mixing nitrile rubber with various fillers, additives, and accelerators to achieve the desired properties. This step is crucial for enhancing features like weather resistance and durability.

2. Calendering The compounded rubber is then processed using a calendering technique, where it is flattened and rolled into sheets of specified thickness. This method ensures uniformity in thickness and texture.

3. Curing The sheets undergo a curing process, typically in a press or oven, where heat and pressure trigger cross-linking in the rubber. This stage solidifies the rubber's structure, enhancing its strength and resistance characteristics.

4. Quality Control After production, the sheets undergo rigorous testing and quality control checks to ensure they meet industry standards and customer requirements.

Benefits of Choosing NBR Rubber Sheets from a Manufacturer

Opting for NBR rubber sheets from a reputable manufacturer can provide numerous advantages

1. Customization Many manufacturers offer customization options, allowing clients to specify dimensions, thickness, and other characteristics to meet their unique needs.

2. Quality Assurance Established manufacturers typically adhere to international quality standards, ensuring that their products are reliable and perform optimally.

3. Technical Support Reputable suppliers often provide technical assistance and guidance in selecting the right type of sheet for specific applications, enhancing the overall customer experience.

4. Cost-Effectiveness Bulk purchasing from a manufacturer can lead to significant savings, making NBR rubber sheets a cost-effective solution for businesses.

5. Sustainability Practices Many modern manufacturers focus on sustainable practices, ensuring that the production of NBR rubber sheets minimizes environmental impact.

Conclusion

NBR rubber sheets are an essential component in numerous industries, known for their resilience, versatility, and excellent performance under pressure. By partnering with a reliable manufacturer that specializes in NBR rubber sheets ranging from 1 to 20 mm in thickness, businesses can ensure they are equipped with high-quality materials suited for their specific needs. Whether for industrial applications, automotive components, or other uses, NBR rubber sheets deliver the performance required to thrive in demanding environments.