Dec . 01, 2024 14:36 Back to list

Suppliers of High-Quality NBR Rubber Sheets from 1 to 20mm Thickness

The Importance of NBR Rubber Sheets Finding Reliable Suppliers

Nitrile Butadiene Rubber (NBR) has emerged as one of the most popular elastomers in various industries due to its excellent resistance to oils, fuels, and chemicals. Often used in gaskets, seals, and other applications, NBR rubber sheets, particularly those ranging from 1mm to 20mm in thickness, are sought after for their versatility and robustness. Finding reliable suppliers for these rubber sheets is crucial for businesses operating in sectors such as automotive, aerospace, oil and gas, and even food processing.

Understanding NBR Rubber

NBR is a copolymer of acrylonitrile and butadiene, which imparts specific characteristics that make it favorable for industrial use. The high acrylonitrile content in NBR enhances its resistance to petroleum products while still maintaining flexibility and durability. This makes NBR rubber sheets particularly useful in high-demand environments where exposure to oils and solvents is common. The thickness of the sheets can vary significantly, with options ranging from as thin as 1mm to as thick as 20mm, allowing for customization based on the requirements of specific applications.

Applications of NBR Rubber Sheets

The applications of NBR rubber sheets are extensive. In the automotive industry, they are used for fuel system seals, gaskets, and hoses. In the oil and gas sector, they serve as linings and seals that withstand harsh conditions. Additionally, in the food processing industry, food-grade NBR rubber sheets are utilized to handle oils and fats safely. The versatility of NBR rubber sheetsn makes finding a trusted supplier essential for ensuring quality and compliance with industry standards.

Factors to Consider When Choosing Suppliers

When searching for suppliers of NBR rubber sheets, there are several key factors to consider

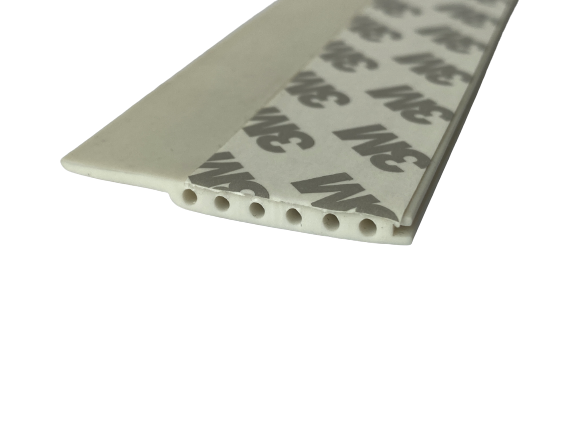

nbr rubber 1~20mm rubber sheet suppliers

1. Quality Assurance The quality of rubber sheets can significantly impact their performance in industrial applications. Suppliers should provide documentation proving that their products meet relevant international standards and certifications.

2. Customization Options Different applications may require specific requirements, including thickness, size, and chemical compatibility. Look for suppliers willing to offer customization options to meet your specific needs.

3. Price and Value While cost is an important factor, consider the overall value. Cheaper products may not always be the best in terms of durability and performance. Compare prices from multiple suppliers, considering both the material quality and the supplier's reputation.

4. Lead Times and Availability Assess the supplier's ability to meet your demand in a timely manner. Inventory levels and lead times can vary, impacting your production schedule. A supplier that can provide rapid delivery will be more beneficial to your operations.

5. Customer Support A reliable supplier should offer excellent customer service, providing technical assistance and guidance on selecting the right rubber sheet for your application. Responsive communication can be a lifesaver when urgent needs arise.

Conclusion

In conclusion, NBR rubber sheets are invaluable across numerous industries due to their outstanding properties. Finding the right supplier is critical for ensuring you receive quality materials that meet your needs and standards. By evaluating suppliers based on quality assurance, customization options, pricing, availability, and customer support, businesses can build effective partnerships that contribute to their success. As the demand for NBR rubber sheets continues to grow, the importance of reliable suppliers cannot be overstated in helping companies thrive in competitive markets. Whether you're involved in automotive manufacturing, oil exploration, or food production, investing time in finding the right NBR rubber sheet supplier can yield substantial long-term benefits.