Dec . 04, 2024 10:58 Back to list

Neoprene Rubber Gasket Sheet for Sealing and Insulation Applications

The Versatility and Importance of Neoprene Rubber Gasket Sheets

Gaskets are essential components in various industries, serving as a crucial barrier to prevent leaks of liquids and gases between two surfaces. Among the diverse assortment of gasket materials available in the market, neoprene rubber stands out due to its unique properties and wide range of applications. Neoprene rubber gasket sheets are particularly popular because of their durability, flexibility, and resistance to environmental factors.

What is Neoprene Rubber?

Neoprene, or polychloroprene, is a synthetic rubber that was first developed in the 1930s as a substitute for natural rubber. It is renowned for its resilience, temperature resistance, and ability to withstand exposure to oils and various chemicals. These properties make neoprene an excellent choice for creating gaskets that demand reliability and endurance under challenging conditions.

Characteristics of Neoprene Rubber Gasket Sheets

1. Chemical Resistance Neoprene rubber exhibits impressive resistance to a variety of chemicals, making it suitable for applications in industries like automotive, aerospace, and food processing. It can withstand exposure to oils, greases, and certain solvents without degrading or losing its integrity.

2. Weather Resistance Neoprene is well-suited for outdoor applications due to its ability to resist UV rays and ozone, which can cause other materials to deteriorate. This characteristic is particularly beneficial for gaskets used in marine or outdoor environments where they may be exposed to harsh conditions.

3. Temperature Tolerance Another essential feature of neoprene rubber is its ability to endure a wide range of temperatures. Neoprene gasket sheets can perform effectively in both high and low-temperature settings, which is critical for applications involving engines, HVAC systems, and industrial machinery.

4. Flexibility and Compression Set Resistance Neoprene’s inherent flexibility allows it to create a tight seal even when subjected to compression. It maintains its shape and performance over time, which reduces the likelihood of leaks and extends the lifespan of both the gasket and the machinery it helps protect.

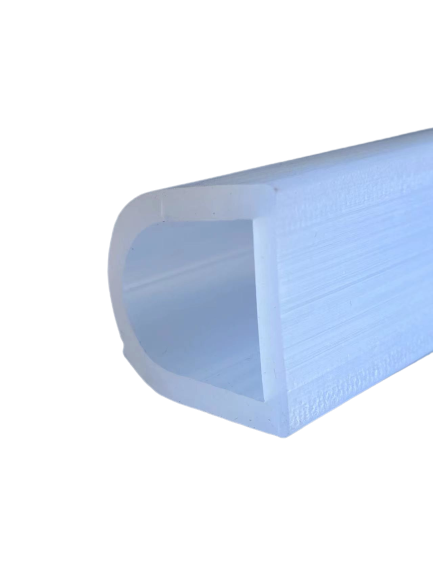

neoprene rubber gasket sheet

Applications of Neoprene Rubber Gasket Sheets

Neoprene rubber gasket sheets are used in numerous sectors, reflecting their versatility

- Automotive Industry Neoprene gaskets are commonly used in engines, fuel systems, and air conditioning units due to their high-temperature capabilities and resilience to oil and chemical exposure.

- Aerospace The aerospace industry benefits from neoprene's lightweight and durable characteristics. It is utilized in fuel systems, hydraulic seals, and other critical applications where leakage could have severe consequences.

- Marine Applications Gasket sheets made from neoprene are widely employed in boat construction and servicing, particularly in engine mounts and hull joints, where water and corrosion resistance are crucial.

- Electronics Neoprene's insulating properties make it a good choice for gaskets in electronic devices, helping protect sensitive components from environmental factors.

- Construction and HVAC In building and HVAC systems, neoprene rubber gaskets are used to seal pipes, ducts, and windows, providing insulation and preventing air leaks, which is vital for energy efficiency.

Conclusion

In conclusion, neoprene rubber gasket sheets are an invaluable asset across numerous industries, providing solutions that ensure the integrity and efficiency of equipment and systems. Their unique properties—chemical resistance, weather resistance, temperature tolerance, and flexibility—underscore their importance in preventing leaks and maintaining functionality. As various sectors continue to evolve and face new challenges, the reliability of neoprene gaskets will remain a cornerstone of modern engineering and manufacturing practices. Whether in vehicles, airplanes, marine vessels, or commercial buildings, neoprene rubber gasket sheets represent a blend of durability and versatility that is hard to match. As industries become more reliant on advanced materials, neoprene is poised to continue playing a vital role in enhancing performance and safety across a myriad of applications.