Oct . 03, 2024 18:55 Back to list

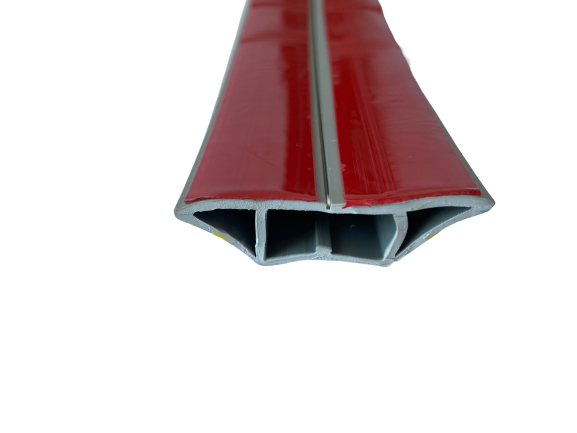

neoprene sponge rubber sheet

Neoprene sponge rubber sheets are versatile materials widely used across various industries due to their unique properties and benefits. Made from neoprene, a synthetic rubber, these sheets combine flexibility, durability, and resistance to environmental factors, making them ideal for an array of applications.

One of the standout features of neoprene sponge rubber sheets is their excellent insulation capabilities

. They provide effective thermal and acoustic insulation, which is essential in industries like construction, automotive manufacturing, and HVAC. By using neoprene sheets, builders can enhance energy efficiency by minimizing heat transfer and reducing noise pollution, creating more comfortable living and working environments.Another significant advantage of neoprene sponge rubber is its resistance to oils, chemicals, and environmental degradation. This property makes it suitable for applications in automotive and marine industries, where exposure to fuels, solvents, and humidity can lead to material failure. Neoprene sheets maintain their integrity in these harsh conditions, ensuring long-lasting performance.

In addition to its physical resilience, neoprene sponge rubber offers a degree of flexibility and elasticity. This makes it an excellent choice for seals, gaskets, and cushioning applications. The ability to compress and return to its original shape allows it to absorb shock and vibrations, providing protection for sensitive equipment or components, such as in electronics or machinery.

neoprene sponge rubber sheet

Manufacturers often provide neoprene sponge rubber sheets in various thicknesses, densities, and sizes, allowing for customization according to specific project requirements. This adaptability is a key factor in its popularity among designers and engineers. Whether it is for a small DIY project or large-scale industrial use, users can find the right neoprene sheet to suit their needs.

Moreover, neoprene sponge rubber is easy to work with. It can be cut, glued, and shaped with standard tools, making it an accessible material for many users. This ease of fabrication, combined with its favorable characteristics, has cemented its place as a go-to material for numerous applications, ranging from protective padding and electrical insulation to waterproofing solutions.

Sustainability is also becoming increasingly important in material selection. Although traditional neoprene production has environmental concerns, advancements in manufacturing processes are leading to more sustainable options. Some suppliers offer eco-friendly neoprene alternatives, which provide the same quality and performance while reducing the ecological footprint.

In conclusion, neoprene sponge rubber sheets serve as a crucial material across various sectors, offering numerous benefits such as insulation, chemical resistance, flexibility, and ease of use. As industries continue to innovate and seek sustainable solutions, the relevance and application of neoprene sponge rubber will likely grow, making it a staple material in modern manufacturing and design processes. Whether it’s for industrial, automotive, or consumer applications, neoprene sponge rubber sheets represent a blend of performance and practicality, meeting the diverse needs of today’s market.