Nov . 15, 2024 16:42 Back to list

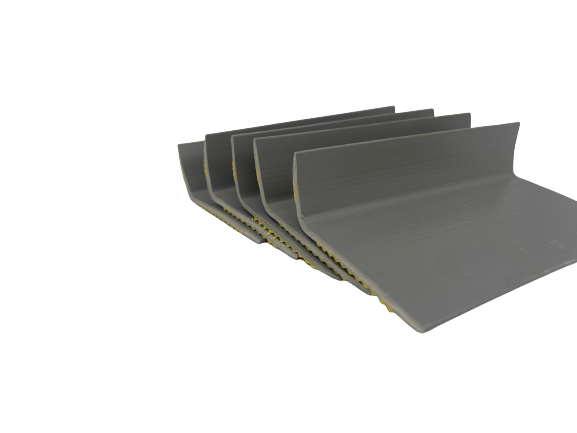

oem epdm composite sponge door sealing strip

Understanding OEM EPDM Composite Sponge Door Sealing Strips

In the world of construction and automotive manufacturing, sealing strips are essential components that contribute significantly to the overall integrity and efficiency of doors and windows. Among the various materials used in the production of these sealing strips, EPDM (Ethylene Propylene Diene Monomer) has emerged as a popular choice, particularly in the form of OEM (Original Equipment Manufacturer) composite sponge door sealing strips. This article delves into the features, benefits, and applications of EPDM composite sponge sealing strips.

What is EPDM?

EPDM is a synthetic rubber known for its exceptional resistance to temperature extremes, UV radiation, ozone degradation, and weathering. Its molecular structure enables it to maintain flexibility and resilience, which makes it ideal for sealing applications. The composite sponge variant of EPDM incorporates a closed-cell sponge structure, offering additional cushioning and compression resistance.

Benefits of OEM EPDM Composite Sponge Door Sealing Strips

1. Durability and Longevity One of the biggest advantages of EPDM sealing strips is their durability. They can withstand harsh environmental conditions and have a long service life, reducing the need for frequent replacements. This is particularly beneficial in industrial settings where sealing integrity is crucial.

2. Sound Insulation The sponge-like nature of these composite strips provides excellent sound insulation, making them ideal for residential and commercial doors. They help in reducing noise pollution by preventing sound from seeping through gaps around doors.

3. Thermal Insulation High-quality EPDM sealing strips also contribute to energy efficiency. They help maintain indoor temperatures by minimizing the airflow between the interior and the outside environment. This is especially important in climates with extreme weather conditions, as reducing the need for heating or cooling can lead to significant energy savings.

oem epdm composite sponge door sealing strip

4. Flexibility and Conformity The flexibility of EPDM composite sponge allows the sealing strips to conform to irregular surfaces and gaps, ensuring a tight seal. This capability is essential in providing a comprehensive solution for various door designs and materials.

5. Ease of Installation OEM EPDM sealing strips are designed for easy installation. They can be cut to size and are often available with adhesive backing, which simplifies the mounting process and reduces installation time.

6. Customization Many manufacturers offer customization options for OEM EPDM sealing strips. Clients can specify dimensions, shapes, and colors to suit specific aesthetic and functional requirements. This level of customization is particularly valuable in OEM applications, where precise specifications are often necessary.

Applications of EPDM Composite Sponge Door Sealing Strips

EPDM composite sponge door sealing strips have a wide range of applications

- Residential Doors These strips are commonly used in home doors to enhance insulation and security while maintaining aesthetic appeal. - Automotive Industry In cars and trucks, EPDM sealing strips are integral to door frames, providing moisture barriers and noise reduction. - Industrial Doors Warehouses and factories benefit from durable EPDM sealing strips that protect against dust, debris, and weather elements. - Commercial Buildings In offices and retail spaces, these strips enhance comfort and energy efficiency, contributing to a better indoor environment.

Conclusion

OEM EPDM composite sponge door sealing strips represent an essential innovation in sealing technology. Their durability, flexibility, and sound and thermal insulation properties make them a preferred choice for various applications. As industries continue to focus on energy efficiency and sustainability, the demand for such high-performing sealing solutions is likely to grow, solidifying EPDM’s role in modern construction and manufacturing. Investing in quality sealing strips not only enhances operational efficiency but also contributes to a more comfortable and sustainable living and working environment.