Sep . 22, 2024 20:36 Back to list

oem other sealing strips

Exploring OEM Other Sealing Strips Importance and Applications

OEM, or Original Equipment Manufacturer, sealing strips play a crucial role in various industries, including automotive, construction, and manufacturing. These specialized components are designed to create airtight and watertight seals, essential for ensuring the functionality and longevity of products. This article delves into the significance of OEM other sealing strips, exploring their types, materials, and applications.

Exploring OEM Other Sealing Strips Importance and Applications

One of the key advantages of OEM sealing strips is their ability to enhance energy efficiency. In automotive applications, for instance, sealing strips reduce airflow leaks, which in turn improves fuel efficiency and reduces greenhouse gas emissions. In buildings, high-quality sealing strips prevent drafts, leading to lower heating and cooling costs. This aspect of sealing strips not only benefits consumers but also contributes to broader environmental sustainability efforts.

oem other sealing strips

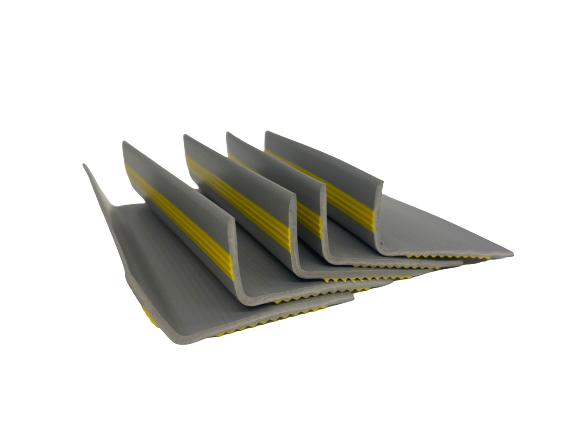

The materials used in OEM sealing strips vary significantly, depending on their application. Common materials include rubber, silicone, foam, and thermoplastic elastomers. Each material has its own set of properties, such as flexibility, durability, and temperature resistance, making it suitable for different conditions. For example, silicone sealing strips are ideal for high-temperature environments, while foam strips may be better suited for applications requiring cushioning and sound dampening.

Applications of OEM other sealing strips are diverse. In the automotive industry, they are used in doors, windows, and trunk lids to prevent water ingress and noise intrusion. In the construction sector, sealing strips are employed in windows and doors to enhance insulation and energy efficiency. Additionally, in industrial machinery, sealing strips help maintain optimal performance by preventing contamination and prolonging the lifespan of components.

The production of OEM sealing strips also involves rigorous testing and quality control processes. Manufacturers must adhere to industry standards and regulations to ensure that the sealing strips are reliable and effective. Customization is another aspect of the OEM process, allowing manufacturers to develop sealing solutions that meet specific needs and performance standards.

In conclusion, OEM other sealing strips are indispensable components that provide essential sealing functionalities across various industries. Their contributions to energy efficiency, product longevity, and cost savings cannot be overstated. As technology advances and industries evolve, the demand for high-quality sealing solutions will only continue to grow, reaffirming the importance of OEM sealing strips in modern manufacturing and beyond.