Feb . 11, 2025 08:30 Back to list

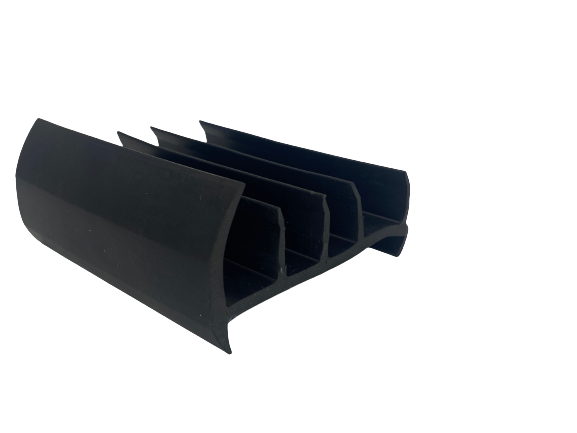

oem rubber seals for doors and windows

Finding the perfect OEM rubber seals for doors and windows requires understanding the nuances of quality, durability, and application specificity. Rubber seals play an indispensable role in ensuring the efficiency and longevity of doors and windows, especially in industrial and residential settings. Here is an in-depth exploration of the attributes that set quality OEM rubber seals apart, gleaned from years of industry experience and expertise.

Authoritatively speaking, the assurance of quality control and reliability inherent in OEM products cannot be understated. These seals are manufactured under stringent quality checks and standards, ensuring that they meet the industry's rigorous requirements. This commitment to excellence not only enhances performance but also establishes a level of trust with users. As such, OEM seals are often the go-to choice for professionals who cannot compromise on quality. Trustworthiness in OEM rubber seals is bolstered by the comprehensive warranty options and support services often provided by manufacturers. This means that in the rare event of a defect or issue, buyers have assured support and recourse, adding a layer of security to their purchase decision. From real-world experience, utilizing OEM rubber seals can lead to significant improvements in energy efficiency for buildings. Proper sealing minimizes air leaks, leading to better climate control and reduced energy costs, an especially important consideration as energy prices soar globally. Furthermore, well-sealed windows and doors contribute to noise reduction, enhancing comfort in both residential and commercial properties. In conclusion, selecting OEM rubber seals for doors and windows boils down to investing in quality, specific application suitability, and long-term reliability. These seals provide a tailored fit, superior durability, and the peace of mind that comes from knowing they are backed by stringent manufacturing standards and reliable support. For industry professionals and homeowners alike, choosing OEM rubber seals ensures that their doors and windows will perform optimally for years to come, providing significant returns on their investment.

Authoritatively speaking, the assurance of quality control and reliability inherent in OEM products cannot be understated. These seals are manufactured under stringent quality checks and standards, ensuring that they meet the industry's rigorous requirements. This commitment to excellence not only enhances performance but also establishes a level of trust with users. As such, OEM seals are often the go-to choice for professionals who cannot compromise on quality. Trustworthiness in OEM rubber seals is bolstered by the comprehensive warranty options and support services often provided by manufacturers. This means that in the rare event of a defect or issue, buyers have assured support and recourse, adding a layer of security to their purchase decision. From real-world experience, utilizing OEM rubber seals can lead to significant improvements in energy efficiency for buildings. Proper sealing minimizes air leaks, leading to better climate control and reduced energy costs, an especially important consideration as energy prices soar globally. Furthermore, well-sealed windows and doors contribute to noise reduction, enhancing comfort in both residential and commercial properties. In conclusion, selecting OEM rubber seals for doors and windows boils down to investing in quality, specific application suitability, and long-term reliability. These seals provide a tailored fit, superior durability, and the peace of mind that comes from knowing they are backed by stringent manufacturing standards and reliable support. For industry professionals and homeowners alike, choosing OEM rubber seals ensures that their doors and windows will perform optimally for years to come, providing significant returns on their investment.

Next:

Prev: