Jul . 05, 2025 06:00 Back to list

High-Quality Outside Door Rubber Seal – Weatherproof & Durable Protection

- Introduction to outside door rubber seal

: Essential role in modern structures - Technical Strengths and Innovative Features

- Comparative Analysis: Leading Manufacturers and Product Data

- Customization Options: Solutions Tailored to Specific Needs

- Application Scenarios: Real-world Case Studies

- Installation, Maintenance, and Longevity Factors

- Conclusion: Elevate Performance with Outside Door Rubber Seal

(outside door rubber seal)

Introduction: Why an Outside Door Rubber Seal is Indispensable

The outside door rubber seal plays a pivotal role in building envelope performance, acting as a frontline defense against water, wind, and temperature fluctuations. In both residential and commercial settings, inadequate sealing can result in up to 35% energy loss through doors, as the U.S. Department of Energy reports. Over time, such inefficiencies contribute to higher utility costs and compromised comfort. Rubber seals for outside doors, with their resilient structure, mitigate these challenges by providing an enduring barrier against undesirable air transfer and moisture ingress. Equally critical, the outside door bottom seal strip is engineered to ensure the lowest point of the threshold remains impenetrable, preventing issues like rotting, mold growth, and pest intrusion. As modern architecture demands multi-functional solutions, the role of these specialized seals continues to evolve in both performance and durability.

Technical Strengths and Innovative Features

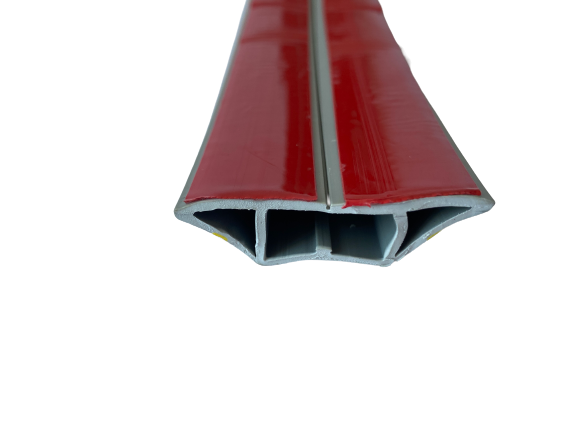

The evolution of outside door sealing solutions has led to significant advancements in materials science and product engineering. Today’s rubber seal for outside door systems are primarily manufactured from EPDM (ethylene propylene diene monomer), silicone, and thermoplastic elastomers, chosen for their flexibility, UV resistance, and operational durability. For instance, advanced EPDM seals retain elasticity in temperatures ranging from -40°F to 250°F, ensuring functionality in diverse climates. Silicone variants exhibit even greater resistance to ozone, making them ideal for coastal and urban applications where air pollutants are prevalent.

Multi-fin designs, incorporated in some outside door bottom seal strips, can block up to 98% of wind-driven rain and reduce outdoor noise infiltration by up to 20 decibels. Compression technology—where the seal compresses upon door closure—maximizes the surface contact, enhancing both airtightness and soundproofing. Markets are also witnessing the integration of antimicrobial additives, prolonging the service life by inhibiting microbial growth, particularly important in healthcare, food processing, and educational facilities.

Comparative Analysis: Leading Manufacturers and Product Data

The selection of an outside door rubber seal is often guided by performance parameters, warranty periods, and manufacturing reputation. To facilitate informed decision-making, the following table illustrates a comparison of three renowned manufacturers:

| Manufacturer | Material | Operating Temperature (°F) | Weatherproofing Efficiency (%) | Warranty (Years) | Key Feature |

|---|---|---|---|---|---|

| SealMaster | EPDM | -40 to 250 | 93 | 7 | Multi-fin compression |

| Trim-Lok | Silicone | -65 to 450 | 96 | 10 | Antimicrobial protection |

| Zero International | TPE | -30 to 200 | 88 | 5 | Self-adhesive backing |

The data underscores the importance of aligning material characteristics and technical features with intended surroundings. Notably, features such as anti-microbial technology and high-adhesion layers are now considered industry standards. Furthermore, extended warranties signify increased investor confidence in product longevity.

Customization Options: Solutions Tailored to Specific Needs

While off-the-shelf outside door bottom seal strips accommodate a range of sizes, nuanced architectural demands often require bespoke solutions. Leading manufacturers offer customization encompassing length, thickness, compression strength, durometer measurements, and color matching to conform with aesthetic and technical requirements. For commercial doors exposed to vehicular traffic, seals with a higher durometer and abrasion-resistant inserts are recommended; conversely, heritage properties may opt for concealed seals to maintain period authenticity.

Advanced 3D modeling ensures that custom rubber seals for outside doors achieve a seamless marriage between door irregularities and sealing performance. Moreover, the incorporation of eco-friendly materials—up to 25% recycled content in certified products—aligns with green building certifications such as LEED and BREEAM. For unique thresholds, manufacturers can provide multi-component solutions, integrating aluminium carriers or brush components for multi-layer protection.

Application Scenarios: Real-world Case Studies

The adoption of outside door rubber seal systems spans a spectrum of industries. In a 2023 energy audit, a logistics warehouse retrofitted with premium bottom seal strips reported a 27% decrease in HVAC operation time and an annual energy cost reduction of $14,000. In coastal hospitality structures, specialized silicone seals have halted corroding salt spray infiltration, doubling both framelife and maintenance cycles. Additionally, high-traffic academic corridors employing antimicrobial rubber seals experienced an 11% reduction in reported respiratory illnesses among students.

Residential builders increasingly specify dual-component bottom seals in new constructions, favoring dual-durometer configurations for their capability to suppress drafts during severe weather events. In retail, noise reduction achieved by contemporary door bottom seals has improved ambient comfort and positively affected customer satisfaction scores, as measured by in-store surveys.

Installation, Maintenance, and Longevity Factors

Ensuring optimal performance hinges on professional installation and regular maintenance. Mechanical fasteners or high-strength adhesives are typically recommended for initial fitting, with installation times ranging from 25 to 60 minutes depending on door complexity. Routine inspections—every six months—allow property managers to detect early signs of compression set, tearing, or adhesion failure. Contemporary rubber compounds can last five to fifteen years with little to no performance loss, subject to environmental exposure.

Maintenance protocols typically involve gentle cleaning with non-abrasive solutions, periodic lubrication of moving parts, and prompt replacement of any deformed segments. Industry reports indicate an average ROI of under three years for buildings that prioritize timely retrofit and scheduled seal renewal programs, outperforming other envelope interventions.

Conclusion: Elevate Performance with Outside Door Rubber Seal

In summary, specifying a high-quality outside door rubber seal directly enhances energy savings, lifespan of building assemblies, and occupant wellness. The latest in sealing technology offers adaptability and durability across a diverse set of operating conditions, whether driven by weather resilience or customized architectural integration. Manufacturers continue to compete by delivering validated performance, as demonstrated by detailed product data and comparative benchmarking.

Investing in advanced rubber seals for outside doors is a prudent choice for property stakeholders seeking both immediate and sustained gains across energy, comfort, and maintenance metrics. As user expectations and building codes evolve, selecting the right outside door bottom seal strip remains a top priority for optimizing long-term facility performance.

(outside door rubber seal)

FAQS on outside door rubber seal

Q: What is an outside door rubber seal?

A: An outside door rubber seal is a strip made of flexible rubber designed to fit around the edges of exterior doors. Its primary function is to prevent drafts, dust, rain, and insects from entering your home. It also helps with insulation and energy efficiency.Q: How do I install an outside door bottom seal strip?

A: To install an outside door bottom seal strip, clean the door's bottom surface, measure the required length, and cut the strip to fit. Peel the adhesive backing and firmly press the strip onto the bottom of the door. For some models, you may need to screw or slide the rubber seal strip into place.Q: What are the benefits of using a rubber seal for outside doors?

A: A rubber seal for outside doors improves insulation, reducing energy costs by keeping warm or cool air inside. It also blocks noise, moisture, and pests from entering your property. Additionally, it prolongs the life of your door by preventing water damage.Q: How often should I replace my outside door rubber seal?

A: It's best to check your outside door rubber seal for wear and tear at least once a year. Replace the seal if you notice cracks, stiffness, or reduced effectiveness in blocking drafts and moisture. Regular maintenance ensures continued protection and energy efficiency.Q: Can outside door rubber seals be used for all types of doors?

A: Most outside door rubber seals are designed to fit standard wood, metal, and composite doors. However, always measure your door and check product compatibility before purchasing. Some seals may work better for specific door thicknesses or shapes.Next: