Jun . 13, 2024 11:15 Back to list

Producer of ship collision prevention seals

The Navigating Force An Insight into Ship's Anti-Collision Seal Manufacturing

In the vast expanse of the maritime world, the safety and security of vessels are paramount concerns. A critical element in ensuring this is the ship's anti-collision seal factory, an industrial powerhouse that plays a pivotal role in maritime safety.

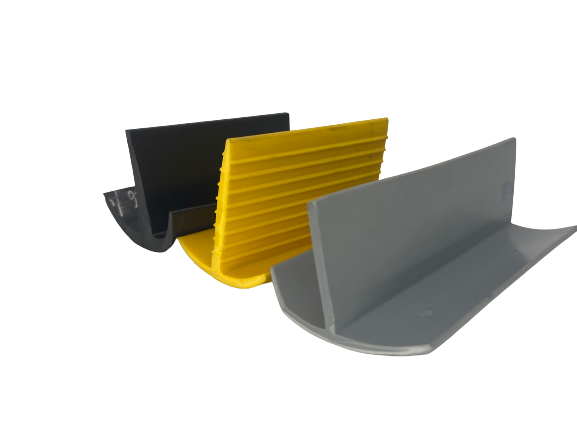

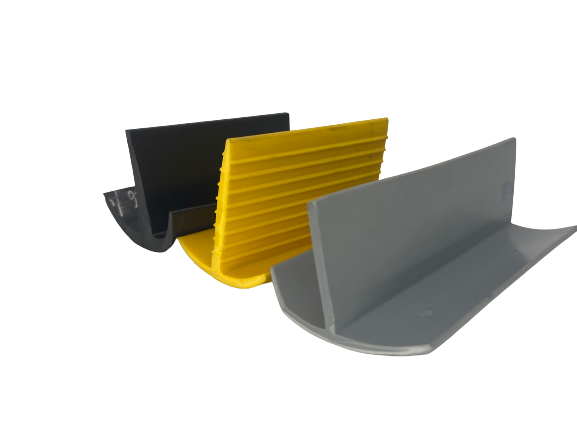

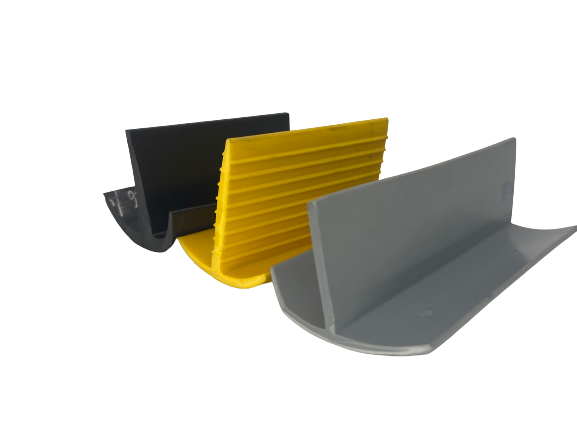

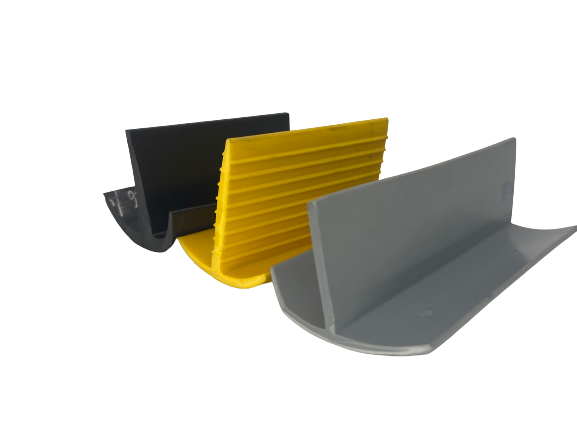

An anti-collision seal, often referred to as a fender system, is a vital component on any vessel. It serves as the first line of defense against damage during berthing or docking procedures, protecting both the ship and port infrastructure from potential collisions. The manufacturing process of these seals is a blend of precision engineering, advanced materials science, and stringent quality control.

The heart of a ship's anti-collision seal factory lies in its engineering team, who design seals tailored to the specific needs of each vessel. They consider factors such as the ship's size, weight, navigation routes, and environmental conditions. Computer-aided design (CAD) software is extensively used to create detailed models, ensuring optimal performance and durability.

Once the design is finalized, the production phase begins. High-grade rubber, often reinforced with steel or other robust materials, is molded into the intricate shapes required for various types of seals. This process requires a high level of precision to guarantee the seal can withstand the immense pressures exerted during berthing.

Quality control is rigorous in these factories. Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear

Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear ship's anti-collision seal factory. These tests include pressure tests, fatigue tests, and environmental simulations to ensure the seals perform reliably in diverse marine environments.

Moreover, the factory also focuses on sustainability. Modern anti-collision seal factories strive to minimize their ecological footprint by using recyclable materials and implementing eco-friendly manufacturing processes. This commitment to green practices not only aligns with global sustainability goals but also contributes to the longevity of the seals, reducing the need for frequent replacements.

Beyond manufacturing, the factory also provides after-sales services. This includes installation guidance, regular maintenance checks, and prompt replacement services when needed. This comprehensive approach ensures that the seals remain effective throughout their operational life.

In conclusion, a ship's anti-collision seal factory is more than just a production facility; it's a guardian of maritime safety. Its work, from the initial design to the final product, is a testament to human ingenuity and a commitment to preventing accidents at sea. The next time you witness a massive vessel smoothly docking at a port, remember the unsung heroes - the anti-collision seals, and the factories that bring them to life.

ship's anti-collision seal factory. These tests include pressure tests, fatigue tests, and environmental simulations to ensure the seals perform reliably in diverse marine environments.

Moreover, the factory also focuses on sustainability. Modern anti-collision seal factories strive to minimize their ecological footprint by using recyclable materials and implementing eco-friendly manufacturing processes. This commitment to green practices not only aligns with global sustainability goals but also contributes to the longevity of the seals, reducing the need for frequent replacements.

Beyond manufacturing, the factory also provides after-sales services. This includes installation guidance, regular maintenance checks, and prompt replacement services when needed. This comprehensive approach ensures that the seals remain effective throughout their operational life.

In conclusion, a ship's anti-collision seal factory is more than just a production facility; it's a guardian of maritime safety. Its work, from the initial design to the final product, is a testament to human ingenuity and a commitment to preventing accidents at sea. The next time you witness a massive vessel smoothly docking at a port, remember the unsung heroes - the anti-collision seals, and the factories that bring them to life.

Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear

Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear Each seal undergoes a series of tests, simulating real-world conditions to verify its strength, elasticity, and resistance to wear and tear ship's anti-collision seal factory. These tests include pressure tests, fatigue tests, and environmental simulations to ensure the seals perform reliably in diverse marine environments.

Moreover, the factory also focuses on sustainability. Modern anti-collision seal factories strive to minimize their ecological footprint by using recyclable materials and implementing eco-friendly manufacturing processes. This commitment to green practices not only aligns with global sustainability goals but also contributes to the longevity of the seals, reducing the need for frequent replacements.

Beyond manufacturing, the factory also provides after-sales services. This includes installation guidance, regular maintenance checks, and prompt replacement services when needed. This comprehensive approach ensures that the seals remain effective throughout their operational life.

In conclusion, a ship's anti-collision seal factory is more than just a production facility; it's a guardian of maritime safety. Its work, from the initial design to the final product, is a testament to human ingenuity and a commitment to preventing accidents at sea. The next time you witness a massive vessel smoothly docking at a port, remember the unsung heroes - the anti-collision seals, and the factories that bring them to life.

ship's anti-collision seal factory. These tests include pressure tests, fatigue tests, and environmental simulations to ensure the seals perform reliably in diverse marine environments.

Moreover, the factory also focuses on sustainability. Modern anti-collision seal factories strive to minimize their ecological footprint by using recyclable materials and implementing eco-friendly manufacturing processes. This commitment to green practices not only aligns with global sustainability goals but also contributes to the longevity of the seals, reducing the need for frequent replacements.

Beyond manufacturing, the factory also provides after-sales services. This includes installation guidance, regular maintenance checks, and prompt replacement services when needed. This comprehensive approach ensures that the seals remain effective throughout their operational life.

In conclusion, a ship's anti-collision seal factory is more than just a production facility; it's a guardian of maritime safety. Its work, from the initial design to the final product, is a testament to human ingenuity and a commitment to preventing accidents at sea. The next time you witness a massive vessel smoothly docking at a port, remember the unsung heroes - the anti-collision seals, and the factories that bring them to life. Next:

Prev: