Nov . 12, 2024 22:40 Back to list

refrigerator door silicone rubber sealing strip exporters

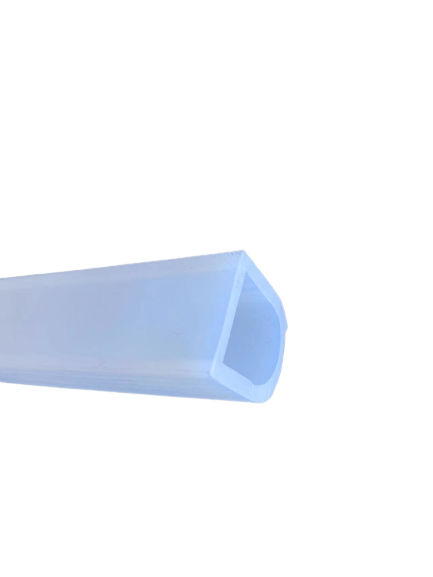

The Importance of Quality Silicone Rubber Sealing Strips in Refrigerator Manufacturing and Exporting

In the realm of modern kitchen appliances, the refrigerator stands as a cornerstone of daily convenience. A pivotal aspect of refrigerator design often overlooked by consumers is the effectiveness of the sealing system, particularly the sealing strip. Among various materials, silicone rubber sealing strips have emerged as a preferred choice for manufacturers and exporters alike. This article delves into the essential qualities of these sealing strips, their manufacturing processes, and the significant role exporters play in the global market.

Why Silicone Rubber?

Silicone rubber is renowned for its superior flexibility, durability, and resistance to temperature fluctuations. These characteristics make it the ideal material for refrigerator door sealing strips. Unlike traditional rubber, silicone does not degrade over time from exposure to cold conditions, ensuring a robust seal that keeps cold air in and warm air out. This maintains the energy efficiency of the refrigerator, consequently lowering electricity consumption and costs for consumers.

The Role of Sealing Strips

Sealing strips serve multiple functions beyond basic insulation. A well-designed strip can prevent moisture ingress, reducing the risk of frost formation inside the refrigerator. This not only improves the overall performance of the appliance but also extends its lifespan. Importantly, high-quality sealing solutions contribute to maintaining optimal food safety and quality, as they prevent cross-contamination and preserve the freshness of stored items.

Manufacturing Quality

The manufacturing of silicone rubber sealing strips requires precision engineering and adherence to strict quality control standards. Manufacturers begin by sourcing high-grade silicone rubber, which is then molded into various shapes and sizes to fit different refrigerator models. The process involves expert craftsmanship and sophisticated machinery that ensure the finished product meets international standards.

refrigerator door silicone rubber sealing strip exporters

Innovations in manufacturing techniques are also enhancing the quality of silicone sealing strips. For instance, the incorporation of additives can improve resistance to UV light and aging, which are critical for products exposed to various environmental conditions. Additionally, the use of eco-friendly processes is becoming increasingly important, as both manufacturers and consumers are now more cognizant of sustainability practices.

Export Market Dynamics

The global demand for refrigerators and their components has prompted a surge in exports of silicone rubber sealing strips. Countries with significant manufacturing capabilities such as China, Germany, and the United States are leading exporters in this sector. The export market for these sealing strips is driven by various factors, including geographical diversification, rising consumer awareness about energy-efficient appliances, and the growing trend of home cooking.

Exporters play a crucial role in this market by connecting manufacturers with international clients. They ensure that the sealing strips meet local regulations and standards in various countries. Moreover, they facilitate logistical aspects, handling shipping, customs, and compliance documentation to streamline the process for manufacturers. Trustworthy exporters are integral to building lasting relationships between producers and buyers, ultimately influencing brand reputation and sales across borders.

Challenges and Solutions

The industry does face challenges regarding quality control and competition from cheaper alternatives. Low-cost products often compromise on quality, leading to shorter lifespan and customer dissatisfaction. However, reputable manufacturers and exporters are countering this challenge by highlighting the long-term benefits of investing in high-quality silicone rubber sealing strips. They are also increasingly focusing on customer education, ensuring that consumers understand the importance of robust sealing solutions in enhancing refrigerator performance.

Conclusion

Silicone rubber sealing strips play an indispensable role in the functionality and efficiency of refrigerators. As the demand for high-quality kitchen appliances continues to grow, the significance of reliable sealing solutions becomes ever more pertinent. Manufacturers and exporters must prioritize quality and innovation to remain competitive in this dynamic market. By doing so, they will not only ensure customer satisfaction but also contribute to a more sustainable and efficient future in home appliance technology. The journey from production to export may be complex, but the ultimate goal remains straightforward delivering superior products that meet the needs of consumers worldwide.