Oct . 05, 2024 00:45 Back to list

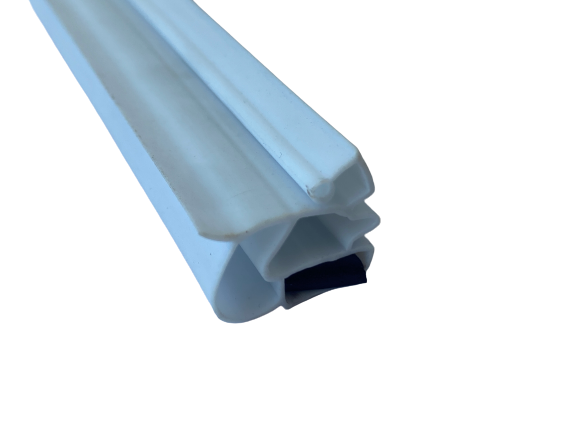

refrigerator door silicone rubber sealing strip factory

The Importance of High-Quality Refrigerator Door Silicone Rubber Sealing Strips A Deep Dive into Manufacturing

When it comes to the functionality and efficiency of refrigerators, the role of sealing strips cannot be overstated. These seemingly minor components are crucial for maintaining the internal temperature of the appliance and ensuring energy efficiency. In this article, we will explore the manufacturing of refrigerator door silicone rubber sealing strips and their significance in the home appliance industry.

What are Silicone Rubber Sealing Strips?

Silicone rubber sealing strips are flexible, durable materials designed to provide a tight seal around refrigerator doors. They prevent the exchange of hot air from the outside with the cold air within, which is essential for the efficiency of refrigeration. These seals not only help in maintaining the desired temperature but also contribute significantly to energy savings by reducing the workload on the compressor.

The Manufacturing Process

The production of silicone rubber sealing strips involves several stages, each crucial in ensuring the final product is of high quality. The process generally includes the following steps

1. Material Selection High-quality silicone rubber is selected based on its elasticity, temperature resistance, and durability. Silicone is favored over traditional rubber for its superior resistance to degradation and performance under varying temperatures.

2. Compounding The raw silicone is mixed with additives to enhance its properties. These additives can include curing agents, pigments, and fillers. The specific formulation can vary depending on the desired characteristics of the final product, such as color and resistance to environmental factors.

3. Molding The compounded silicone is then placed into molds. This can be done through various methods, such as compression molding or extrusion. In compression molding, the silicone is heated and compressed into the mold, while in extrusion, the material is forced through a die to create long strips that will later be cut to size.

4. Curing After molding, the silicone undergoes curing, a process that transforms it from a pliable material into a durable rubber. This can be achieved through heat, which triggers a chemical reaction that solidifies the silicone.

refrigerator door silicone rubber sealing strip factory

5. Quality Control Once cured, the sealing strips are subjected to rigorous quality control tests. These tests assess properties such as dimensional accuracy, tensile strength, and environmental resistance. Only products that meet strict quality standards are approved for use in refrigerators.

6. Cutting and Packaging Finally, the cured and tested sealing strips are cut to specific lengths and packaged for distribution. Effective packaging ensures that the seals remain intact and usable upon arrival at their destination.

The Benefits of Silicone Rubber Sealing Strips

The advantages of using silicone rubber sealing strips over other materials are manifold

- Durability Silicone rubber seals are resistant to wear and tear, making them an excellent choice for appliances that see frequent use.

- Temperature Resistance These seals remain flexible and functional even at extreme temperatures, ensuring a reliable seal over time.

- Energy Efficiency By preventing warm air from entering, silicone seals play a vital role in reducing energy consumption, ultimately saving consumers money on their electric bills.

- Hygienic Properties Silicone is naturally resistant to mold and bacteria, making it a hygienic option for kitchen appliances where food is stored.

Conclusion

In summary, the manufacturing of refrigerator door silicone rubber sealing strips is a critical process that requires precision and attention to detail. These seals are not just minor components; they are essential for the overall performance and efficiency of refrigeration. As consumers become increasingly aware of their environmental impact, the demand for energy-efficient appliances will continue to rise. Therefore, investing in high-quality silicone rubber sealing strips will not only enhance appliance performance but also contribute to sustainable living practices. As the industry evolves, manufacturers must remain committed to quality and innovation in order to meet the needs of modern consumers.