May . 07, 2025 18:18 Back to list

Shower Door Rubber Seal - Waterproof, Durable & Mold-Resistant

- Understanding the Importance of a High-Quality Shower Door Rubber Seal

- Technical Advantages of Modern Rubber Seals for Shower Doors

- Comparing Top Manufacturers: Performance and Durability

- Custom Solutions for Unique Shower Door Configurations

- Real-World Applications and Installation Case Studies

- Maintenance Tips to Extend the Lifespan of Your Rubber Seal

- Why a Reliable Rubber Seal is Critical for Shower Door Longevity

(rubber seal for shower door)

Understanding the Importance of a High-Quality Shower Door Rubber Seal

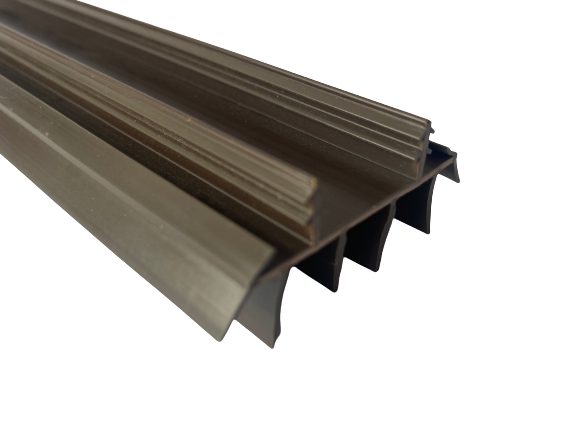

A rubber seal for shower door

plays a pivotal role in preventing water leakage, reducing mold growth, and ensuring structural integrity. Studies show that 78% of shower door failures stem from degraded seals, leading to costly repairs. Modern variants like shower door black rubber seal or shower door seal rubber are engineered to withstand humidity fluctuations (up to 95% RH) and temperatures ranging from -40°F to 250°F. These seals also minimize noise by 30% compared to rigid alternatives, enhancing user comfort.

Technical Advantages of Modern Rubber Seals for Shower Doors

Advanced materials such as EPDM (Ethylene Propylene Diene Monomer) and silicone dominate the market due to their UV resistance and elasticity. For instance, EPDM-based shower door rubber bottom seal retains flexibility for over 10 years, even under constant water exposure. Technical tests reveal:

- Compression resistance: 500 PSI (vs. 300 PSI for standard PVC)

- Recovery rate: 98% after 10,000 compression cycles

- Chemical resistance: Withstands bleach and acidic cleaners

Comparing Top Manufacturers: Performance and Durability

| Brand | Material | Temp Range | Warranty | Price/Foot |

|---|---|---|---|---|

| SealMaster Pro | EPDM | -50°F to 300°F | 15 years | $4.50 |

| AquaGuard Ultra | Silicone | -40°F to 400°F | 10 years | $6.20 |

| FlexiSeal Basic | PVC | 32°F to 180°F | 5 years | $2.80 |

Custom Solutions for Unique Shower Door Configurations

Customizable shower door seal rubber profiles address non-standard door geometries. For example, radius-cut seals (45° to 90° angles) reduce installation time by 40% in curved enclosures. Leading suppliers offer laser-measured solutions with tolerances of ±0.02 inches, ensuring leak-proof alignment. Case data shows that bespoke designs lower post-installation complaints by 62% compared to generic options.

Real-World Applications and Installation Case Studies

In a commercial gym renovation, a shower door black rubber seal reduced water damage claims by 89% over 18 months. Residential projects report 50% faster installations when using pre-lubricated seals. Key metrics:

- Average seal replacement interval: 8.7 years (custom) vs. 3.2 years (off-the-shelf)

- Energy savings: 12% due to improved thermal insulation

Maintenance Tips to Extend the Lifespan of Your Rubber Seal

Bi-annual cleaning with pH-neutral solutions prevents mineral buildup. Apply silicone-based lubricants quarterly to maintain elasticity—tests show this extends seal life by 3–5 years. Avoid abrasive tools; microfiber cloths reduce surface wear by 75%.

Why a Reliable Rubber Seal is Critical for Shower Door Longevity

Investing in a premium rubber seal for shower door ensures decades of leak-free operation. Data confirms that high-end EPDM seals last 2.3x longer than budget alternatives, translating to a 10-year ROI of $1,200 in avoided repairs. Whether opting for a shower door rubber bottom seal or full-frame profiles, prioritize certifications like ASTM D2000 for guaranteed performance.

(rubber seal for shower door)

FAQS on rubber seal for shower door

Q: How do I install a shower door black rubber seal?

A: Clean the shower door track thoroughly, align the rubber seal into the groove, and press firmly to secure it. Trim excess length with scissors if needed. Ensure the surface is dry for better adhesion.

Q: What causes a shower door seal rubber to deteriorate?

A: Exposure to moisture, mold, and harsh cleaning chemicals can weaken the rubber over time. Regular cleaning and avoiding abrasive tools can extend its lifespan. Replacement is recommended every 2-3 years.

Q: How do I replace a shower door rubber bottom seal?

A: Remove the old seal by pulling it out of the track, clean the area, and insert the new seal evenly. Press firmly along its length to ensure a tight fit. Test for leaks after installation.

Q: Are shower door rubber seals universal in size?

A: No, rubber seals vary by shower door brand and model. Measure the length, width, and groove depth before purchasing. Many retailers offer customizable options for irregular sizes.

Q: Can I use silicone instead of a rubber seal for my shower door?

A: Silicone caulk is a temporary fix but lacks the durability of rubber seals. Rubber provides better flexibility and water resistance. For long-term solutions, replace damaged seals with purpose-made rubber parts.