Jun . 28, 2024 02:00 Back to list

Rubber Sealing Solutions for Aluminum Alloy Door and Window Applications

Enhancing Aluminum Alloy Doors and Windows with Rubber Sealing Strips

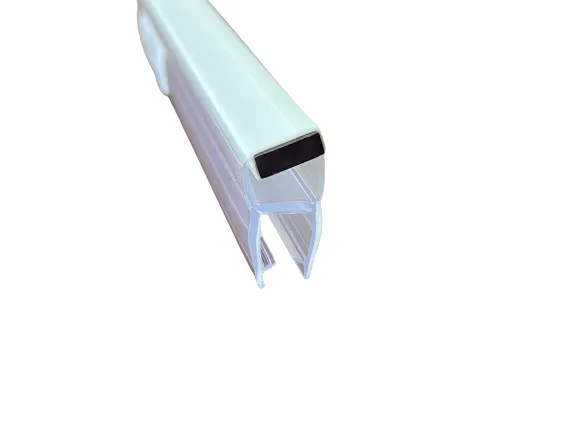

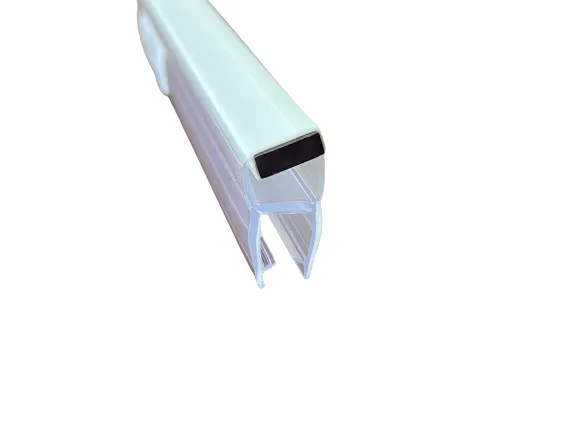

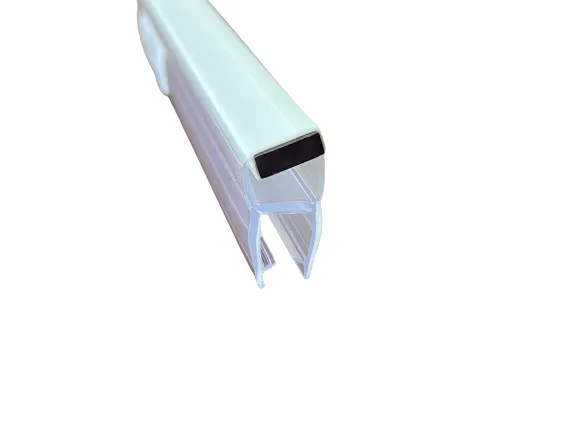

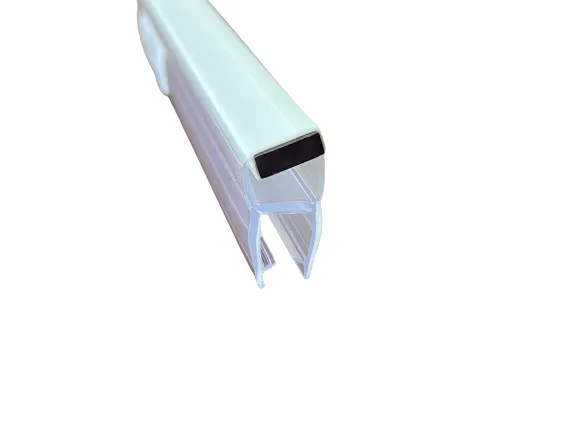

The integration of rubber sealing strips in the construction of aluminum alloy doors and windows is a testament to modern architectural design's commitment to efficiency and durability. These flexible, yet resilient components play a pivotal role in enhancing the performance of such fixtures, ensuring that they not only meet aesthetic standards but also functional requirements.

Aluminum alloy, known for its strength-to-weight ratio and resistance to corrosion, serves as an ideal material for constructing doors and windows. However, the rigidity of this metal can sometimes pose challenges in creating an airtight seal. This is where the rubber sealing strip comes into play. The elastic nature of rubber allows it to conform to irregularities along the frame, effectively preventing drafts and reducing sound transmission.

Moreover, these strips are often designed with weatherproofing capabilities, protecting against moisture infiltration, dust particles, and even insects. In climates prone to extreme temperatures or heavy rainfall, the presence of a high-quality rubber seal can mean the difference between a cozy indoor environment and one plagued by drafts and leaks.

Manufacturers have taken note of this necessity and now offer rubber sealing strips in various profiles to suit different designs and applications. From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful

From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful rubber sealing strip for aluminum alloy doors and windows. Some strips are even equipped with a foam core for added insulation, further improving energy efficiency.

The installation of these strips requires precision, as any gap or misalignment can compromise their performance. Professionals often use specialized tools to ensure the strips are fitted snugly within the frame, maximizing their effectiveness. It's also essential to choose sealing strips made from high-quality rubber that can withstand the elements without cracking or deteriorating over time.

In conclusion, the synergy between aluminum alloy doors and windows and rubber sealing strips epitomizes the harmonious blend of form and function. By addressing both aesthetic appeal and practical concerns such as energy conservation, noise reduction, and environmental protection, these components elevate the standard of residential and commercial structures. As technology advances, it will be exciting to witness how innovations in materials and design continue to enhance the role of rubber sealing strips in modern architecture.

rubber sealing strip for aluminum alloy doors and windows. Some strips are even equipped with a foam core for added insulation, further improving energy efficiency.

The installation of these strips requires precision, as any gap or misalignment can compromise their performance. Professionals often use specialized tools to ensure the strips are fitted snugly within the frame, maximizing their effectiveness. It's also essential to choose sealing strips made from high-quality rubber that can withstand the elements without cracking or deteriorating over time.

In conclusion, the synergy between aluminum alloy doors and windows and rubber sealing strips epitomizes the harmonious blend of form and function. By addressing both aesthetic appeal and practical concerns such as energy conservation, noise reduction, and environmental protection, these components elevate the standard of residential and commercial structures. As technology advances, it will be exciting to witness how innovations in materials and design continue to enhance the role of rubber sealing strips in modern architecture.

From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful

From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful From compression strips that are pressed into place to provide a tight seal, to sweeps that brush against the threshold to keep out debris, the options are plentiful rubber sealing strip for aluminum alloy doors and windows. Some strips are even equipped with a foam core for added insulation, further improving energy efficiency.

The installation of these strips requires precision, as any gap or misalignment can compromise their performance. Professionals often use specialized tools to ensure the strips are fitted snugly within the frame, maximizing their effectiveness. It's also essential to choose sealing strips made from high-quality rubber that can withstand the elements without cracking or deteriorating over time.

In conclusion, the synergy between aluminum alloy doors and windows and rubber sealing strips epitomizes the harmonious blend of form and function. By addressing both aesthetic appeal and practical concerns such as energy conservation, noise reduction, and environmental protection, these components elevate the standard of residential and commercial structures. As technology advances, it will be exciting to witness how innovations in materials and design continue to enhance the role of rubber sealing strips in modern architecture.

rubber sealing strip for aluminum alloy doors and windows. Some strips are even equipped with a foam core for added insulation, further improving energy efficiency.

The installation of these strips requires precision, as any gap or misalignment can compromise their performance. Professionals often use specialized tools to ensure the strips are fitted snugly within the frame, maximizing their effectiveness. It's also essential to choose sealing strips made from high-quality rubber that can withstand the elements without cracking or deteriorating over time.

In conclusion, the synergy between aluminum alloy doors and windows and rubber sealing strips epitomizes the harmonious blend of form and function. By addressing both aesthetic appeal and practical concerns such as energy conservation, noise reduction, and environmental protection, these components elevate the standard of residential and commercial structures. As technology advances, it will be exciting to witness how innovations in materials and design continue to enhance the role of rubber sealing strips in modern architecture.