Aug . 21, 2024 22:26 Back to list

rubber sealing solutions for doors and windows manufacturing company

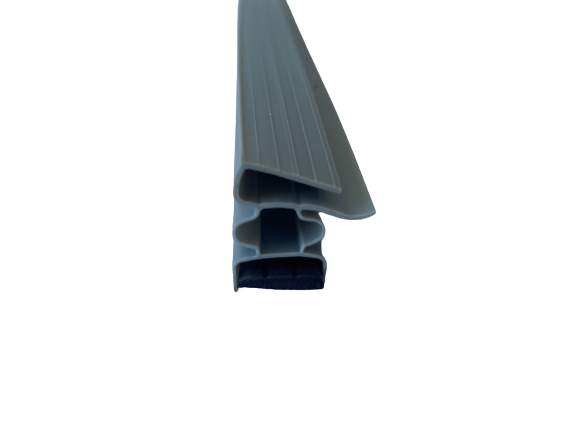

Rubber Seals for Doors and Windows A Comprehensive Overview

In today's world, where energy efficiency and durability are paramount, rubber seals for doors and windows play a crucial role. These seals are the unsung heroes of insulation, ensuring that our homes and offices maintain a comfortable environment while reducing energy costs. The market for rubber seals has evolved significantly, with factories developing innovative solutions tailored to meet the diverse needs of consumers.

Rubber seals are primarily designed to provide a tight barrier against air, water, and dust infiltration. They are an essential component in enhancing the energy efficiency of buildings by preventing heat loss during winter and keeping cool air inside during summer. A well-sealed entry point can significantly reduce the workload on heating and cooling systems, leading to lower energy bills and a reduced carbon footprint.

A variety of rubber materials are used in the manufacturing of these seals, including natural rubber, neoprene, silicone, and EPDM (ethylene propylene diene monomer). Each material has unique properties that make it suitable for specific applications. For instance, silicone rubber is known for its excellent temperature resistance and flexibility, making it ideal for high-performance applications. On the other hand, EPDM is renowned for its weather resistance and longevity, making it perfect for outdoor applications, such as sealing windows and doors in harsh climates.

Factories that specialize in the production of rubber seals for doors and windows employ advanced technologies and equipment to ensure high-quality products. The manufacturing process typically involves mixing rubber compounds, extrusion, and molding. The formulation of the rubber compound is critical, as it directly affects the seal’s performance characteristics, including flexibility, durability, and resistance to environmental factors.

rubber seals for doors and windows factory

Importantly, quality control is a major focus in the production process. Factories often conduct rigorous testing to ensure that the seals meet industry standards and customer specifications. Tests may include evaluations of tensile strength, elongation, compression set, and resistance to UV radiation. By adhering to strict quality control measures, manufacturers ensure that their seals provide long-lasting performance and reliability.

The application of rubber seals extends beyond residential doors and windows. They are used in commercial buildings, vehicles, and appliances. In commercial applications, robust seals contribute significantly to energy savings and occupant comfort. In vehicles, seals help reduce noise and vibration, enhancing the driving experience. Meanwhile, in appliances like refrigerators and washing machines, they play a vital role in maintaining efficiency and preventing leaks.

Innovative designs and custom solutions are central to the success of rubber seal manufacturers. Many factories offer tailored services, allowing customers to specify dimensions and materials that best fit their unique requirements. For instance, custom sealing solutions are crucial for antique windows or unusual door sizes, where standard seals may not be adequate.

Sustainability is another key consideration for modern rubber seal factories. As environmental consciousness grows, many manufacturers are exploring eco-friendly materials and processes. The integration of recycled rubber materials into production lines is one such initiative aimed at reducing environmental impact while maintaining product performance.

In conclusion, rubber seals for doors and windows are essential components in modern construction and manufacturing. With advancements in materials and manufacturing techniques, these seals not only enhance energy efficiency and comfort but also adapt to various applications across multiple industries. As we continue to prioritize sustainability and innovation, the future of rubber seals remains bright, promising even more efficient and durable solutions for consumers worldwide.