Jul . 27, 2024 17:30 Back to list

Rubber Seals for Doors and Windows Manufacturing Solutions and Industry Applications

The Importance of Rubber Seals for Doors and Windows in Factories

In the manufacturing sector, the need for efficiency and reliability is paramount. One often overlooked component that plays a crucial role in achieving these goals is the rubber seal for doors and windows. These seals are essential for ensuring energy efficiency, improving safety, and enhancing the overall performance of a factory’s infrastructure.

Energy Efficiency and Cost Savings

Rubber seals are designed to create a tight barrier between the indoor environment and the external elements. In factories, where heating and cooling can represent a significant operational cost, these seals help maintain temperature control. By preventing drafts and heat loss, rubber seals contribute to a stable internal climate, which can reduce energy consumption. This not only leads to cost savings but also supports sustainability initiatives by reducing the factory's carbon footprint.

Furthermore, a well-sealed environment protects sensitive machinery and equipment from adverse weather conditions. In industries where precision and consistency are vital, ensuring that machinery operates under stable conditions is crucial. Rubber seals help achieve this by keeping moisture, dust, and other pollutants at bay, prolonging the lifespan of machines and reducing maintenance costs.

Safety and Compliance

Safety is a critical concern for any factory. Rubber seals add an extra layer of protection by ensuring that doors and windows close securely, minimizing the risk of accidents. By preventing unauthorized access, these seals contribute to the overall security of the facility, protecting valuable assets and sensitive information.

Moreover, many industries are subject to stringent safety regulations. Properly installed rubber seals can help factories comply with these regulations by providing barriers against fire, smoke, and other hazards. For example, fire-rated rubber seals are essential in maintaining the integrity of fire door systems, helping to contain fires and smoke, and allowing for safer evacuation during emergencies.

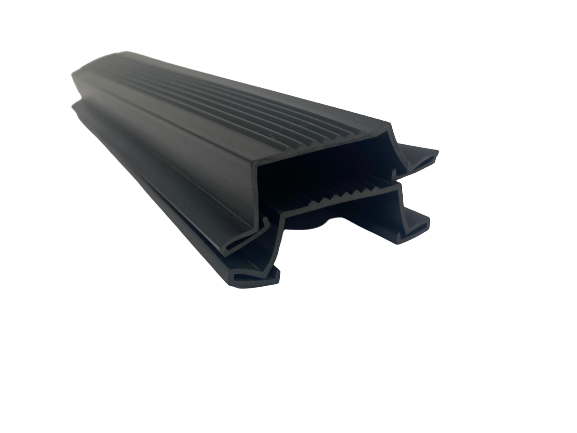

rubber seals for doors and windows factories

Noise Reduction

In factories, noise pollution is another pressing issue. Machinery, equipment, and operational processes can create a noisy environment that hampers concentration and productivity. Rubber seals play a pivotal role in sound insulation. By sealing gaps around doors and windows, they significantly reduce the transmission of noise from inside and outside the facility. This not only enhances worker comfort but also improves overall productivity by allowing employees to focus on their tasks without unnecessary distractions.

Durability and Versatility

Rubber is a material known for its durability and adaptability. It can withstand various environmental conditions, including extreme temperatures and humidity. This robustness makes rubber seals suitable for different types of factory settings, whether they are food processing plants that require strict hygiene standards or manufacturing units exposed to harsh chemicals.

Moreover, rubber seals come in a variety of shapes, sizes, and formulations, allowing for customized solutions tailored to specific needs. Factories can choose from different seal profiles to match their door and window designs, ensuring a perfect fit that enhances performance.

Conclusion

In conclusion, rubber seals for doors and windows are indispensable components of factory infrastructure. They contribute to energy efficiency, enhance safety and compliance, reduce noise pollution, and offer durability and versatility. By investing in high-quality rubber seals, factories can not only safeguard their operations but also improve overall efficiency and productivity. As the manufacturing industry continues to evolve, the importance of these often-neglected components will undoubtedly become more pronounced, highlighting the need for factories to prioritize their implementation in their operational strategies.