Sep . 21, 2024 12:30 Back to list

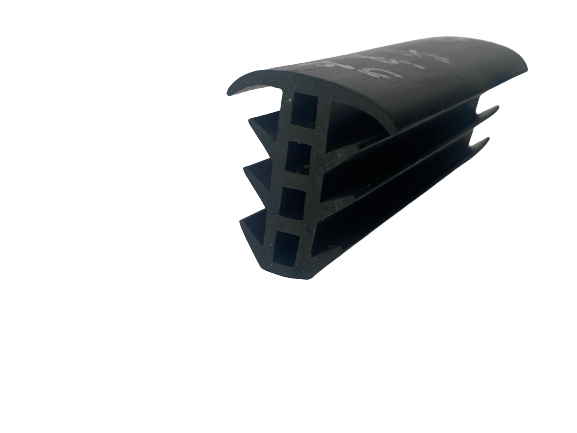

rubber edge sealing strip

The Importance of Rubber Edge Sealing Strips in Modern Applications

In today's fast-paced world, maintaining efficiency and quality in various industries is paramount. One often-overlooked component that plays a crucial role in enhancing product integrity is the rubber edge sealing strip. This simple yet effective solution is essential in providing protection, insulation, and aesthetic appeal across a wide range of applications.

Rubber edge sealing strips are designed to fit around the edges of different surfaces, effectively sealing gaps and preventing the intrusion of dust, moisture, and other environmental factors. These strips are made from high-quality rubber, allowing them to be flexible and resilient while offering exceptional durability. Their versatility makes them suitable for use in various sectors, including automotive, construction, manufacturing, and more.

One of the primary uses of rubber edge sealing strips is in automotive applications. Vehicles are constantly exposed to harsh weather conditions, and maintaining a sealed environment is vital for the comfort and safety of passengers. Rubber edge seals protect against wind, rain, and noise while also preventing the entry of harmful pollutants. They play a key role in enhancing the overall driving experience, contributing significantly to the thermal insulation and soundproofing of vehicles.

In the construction industry, rubber edge sealing strips are invaluable in ensuring the longevity of structures. These strips are commonly used around windows, doors, and other openings to prevent drafts and water leaks. By effectively sealing these edges, they help maintain energy efficiency, reduce heating and cooling costs, and promote a more comfortable living environment. Additionally, their installation can help prevent damage to building materials, ultimately extending the lifespan of the structure.

rubber edge sealing strip

The manufacturing sector also benefits greatly from rubber edge sealing strips. In factories, machinery and equipment often produce excessive vibrations and noise, which can lead to equipment wear and employee discomfort. By applying rubber edge seals to machinery and workstations, manufacturers can mitigate these issues, creating a safer and more productive workspace. Moreover, sealing measures can prevent contamination, particularly in industries that require a clean environment, such as food processing and pharmaceuticals.

Aesthetic considerations are another significant factor in the use of rubber edge sealing strips. Many designers and architects prefer to incorporate these seals into their projects to create a polished and professional appearance. The various colors, sizes, and shapes available allow for seamless integration into different design schemes, ensuring that functionality does not compromise visual appeal.

Installing rubber edge sealing strips is a straightforward process that requires minimal tools and expertise. These strips can be cut to size and adhered using adhesives or mechanical fasteners, making them an accessible solution for both DIY enthusiasts and professionals. Regular maintenance and inspection are also essential to ensure their effectiveness over time, as wear and tear can impact their sealing capabilities.

In conclusion, rubber edge sealing strips are a crucial component in various industries, providing protection, insulation, and aesthetic benefits. Their versatility and durability make them an indispensable choice for ensuring product integrity and enhancing user experience. As technology and design continue to evolve, the demand for rubber edge sealing strips will undoubtedly grow, paving the way for innovative applications and solutions that meet the challenges of modern life.

Next:

Prev: