Dec . 26, 2024 23:23 Back to list

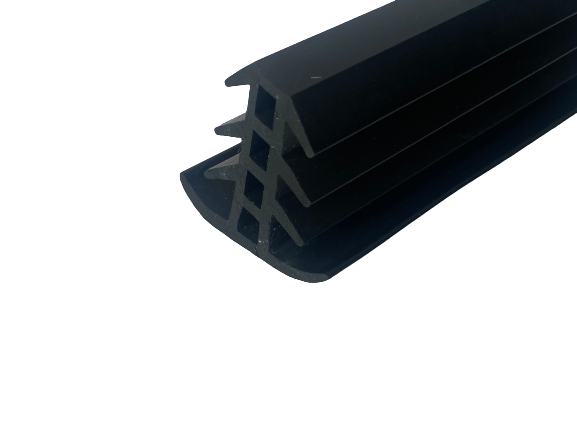

rubber gasket rolls

Understanding Rubber Gasket Rolls Essential Components for Sealing Solutions

Rubber gasket rolls are a crucial component in a wide array of industries, providing effective sealing solutions for numerous applications. These rolls, made from various types of rubber materials, offer flexibility, durability, and resistance to various environmental factors, making them ideal for both manufacturing and repair processes. This article delves into the properties, applications, and advantages of rubber gasket rolls, highlighting their essential role in ensuring effective sealing.

What are Rubber Gasket Rolls?

Rubber gasket rolls are sheets of rubber material that can be cut into gaskets of various shapes and sizes. They are typically available in different thicknesses, widths, and lengths, allowing for customization to meet specific requirements. The most common materials used in rubber gasket rolls include neoprene, silicone, EPDM (ethylene propylene diene monomer), Nitrile, and Viton. Each of these materials has distinct properties, making them suitable for different environments and applications.

Properties of Rubber Gasket Rolls

1. Flexibility One of the standout features of rubber gasket rolls is their flexibility. This property allows them to conform to the surfaces they are sealing, ensuring a tight fit and preventing leaks.

2. Temperature Resistance Many rubber materials used in gasket production have excellent temperature resistance, allowing them to perform well in both high and low-temperature environments.

3. Chemical Resistance Depending on the type of rubber used, gasket rolls can exhibit resistance to various chemicals, oils, and solvents, making them suitable for industrial applications where exposure to harsh substances is common.

4. Compression Set Resistance Rubber gaskets maintain their shape and sealing ability over time, thanks to their resistance to compression set. This means that, even after prolonged use, they can still provide an effective seal without significant deformation.

Applications of Rubber Gasket Rolls

Rubber gasket rolls find applications across multiple industries

rubber gasket rolls

2. Aerospace The aerospace industry utilizes rubber gaskets to seal various systems, such as fuel tanks and hydraulic systems, ensuring safety and functionality.

3. Manufacturing Rubber gaskets are extensively used in manufacturing machinery to prevent leaks in hydraulic and pneumatic systems, thereby enhancing efficiency.

4. Plumbing In plumbing applications, rubber gasket rolls are utilized to create seals in pipe fittings and flanges, preventing water leaks and ensuring a reliable plumbing system.

5. Electrical In electrical applications, rubber gaskets are used to seal electrical enclosures, protecting sensitive components from moisture and dust.

Advantages of Using Rubber Gasket Rolls

1. Cost-Effectiveness Rubber gasket rolls provide a cost-effective solution for businesses requiring gaskets in bulk. The ability to cut the rolls into custom shapes as needed further enhances their value.

2. Ease of Use Rubber gaskets are easy to work with and can be cut to size using standard tools, allowing for quick installation and replacement.

3. Customizability Many suppliers offer rubber gasket rolls in various sizes and thicknesses, allowing customers to customize their gaskets to meet specific needs.

4. Long Lifespan When properly maintained, rubber gasket rolls can last for an extended period, minimizing the need for frequent replacements and associated costs.

Conclusion

Rubber gasket rolls are an indispensable part of modern industrial applications, providing reliable sealing solutions in various settings. Their versatility, combined with the benefits they offer, makes them a preferred choice for many manufacturers and repair services. With advancements in rubber technology, the future of rubber gasket rolls looks promising, as they continue to evolve to meet the demands of increasingly complex industrial applications. Whether used in automotive, aerospace, manufacturing, or plumbing, rubber gasket rolls play a vital role in maintaining efficiency, safety, and performance across a multitude of industries.