Oct . 06, 2024 06:03 Back to list

rubber sealing strip for aluminum alloy doors and windows exporters

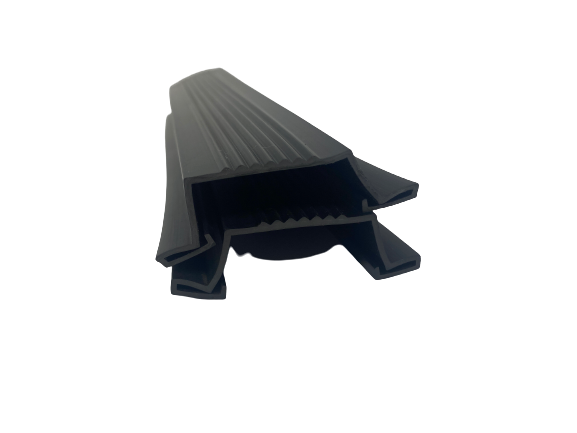

Exploring the Market for Rubber Sealing Strips for Aluminum Alloy Doors and Windows

In recent years, the demand for high-quality rubber sealing strips for aluminum alloy doors and windows has surged. This increase is primarily attributed to the growing construction industry and the rising need for energy-efficient and durable building materials. Rubber sealing strips play a crucial role in enhancing the performance and longevity of aluminum doors and windows, making them a significant component in the construction and manufacturing sectors.

Rubber sealing strips are essential for creating airtight and watertight seals around doors and windows. They help prevent air leaks, which can lead to energy loss and increased utility costs. Furthermore, these seals protect against water infiltration, which can cause damage to the interior of buildings and promote mold growth. The ability of rubber to maintain its flexibility and integrity over time makes it an ideal material for these applications.

Exporters of rubber sealing strips are witnessing robust growth opportunities in the global market. This demand is fueled by the expanded use of aluminum alloy in modern architecture due to its lightweight, strength, and corrosion resistance. As more builders and architects opt for aluminum doors and windows, the need for reliable sealing solutions becomes increasingly paramount.

rubber sealing strip for aluminum alloy doors and windows exporters

Key factors that exporters should consider when entering the market include the quality of the rubber used, compliance with international standards, and the ability to customize products according to customer specifications. High-quality rubber materials not only enhance the performance of the sealing strips but also ensure longevity. Exporters that can provide products compliant with recognized standards such as ISO or ASTM are likely to gain a competitive edge.

Furthermore, innovations in manufacturing processes have led to the development of advanced rubber sealing strips that offer improved performance characteristics. For instance, some newer products are designed to withstand extreme weather conditions, enhancing their durability and effectiveness in sealing. Additionally, the incorporation of environmentally friendly materials into the manufacturing process is becoming increasingly attractive to customers who prioritize sustainability.

As the demand for aluminum alloy doors and windows continues to grow, the potential for rubber sealing strip exporters to thrive is undeniable. Establishing strong relationships with manufacturers, understanding market trends, and prioritizing product quality will be key to success in this field.

In conclusion, the market for rubber sealing strips tailored for aluminum alloy doors and windows presents significant opportunities for exporters. By focusing on high-quality materials and innovative solutions, they can position themselves effectively in this competitive landscape. As the construction industry evolves, those who adapt to changing needs and leverage technological advancements will be best positioned to succeed in the global marketplace.